Predictive engineering in action: how SlizeR anticipates printing results

1. From predictive control to printing

In the Roboze production workflow, quality is not a final check. It’s a design constraint. Every component must meet the dimensions, geometries, and mechanical properties defined in the digital phase, even before the machine begins to move.

This is the foundation of SlizeR, a software developed not only to generate toolpaths, but to embed physical knowledge, process data, and predictive modeling into every slicing decision.

SlizeR interprets the thermomechanical behavior of materials, evaluates heated chamber dynamics, and anticipates the effects of geometric transitions. The result is a deeply engineered approach to additive manufacturing: rather than correcting errors afterward, it prevents them by building a reliable prediction of what will happen during production.

2. Automatic Compensations: in SlizeR, every polymer “knows itself”

One of the distinctive aspects of Roboze predictive engineering lies in the integration, directly within material profiles, of each polymer’s specific shrinkage and expansion coefficients. In other words, every material carries with it its thermal response.

SlizeR uses this data to automatically apply targeted dimensional compensations, adapted not only to the material but also to the geometry of the part.

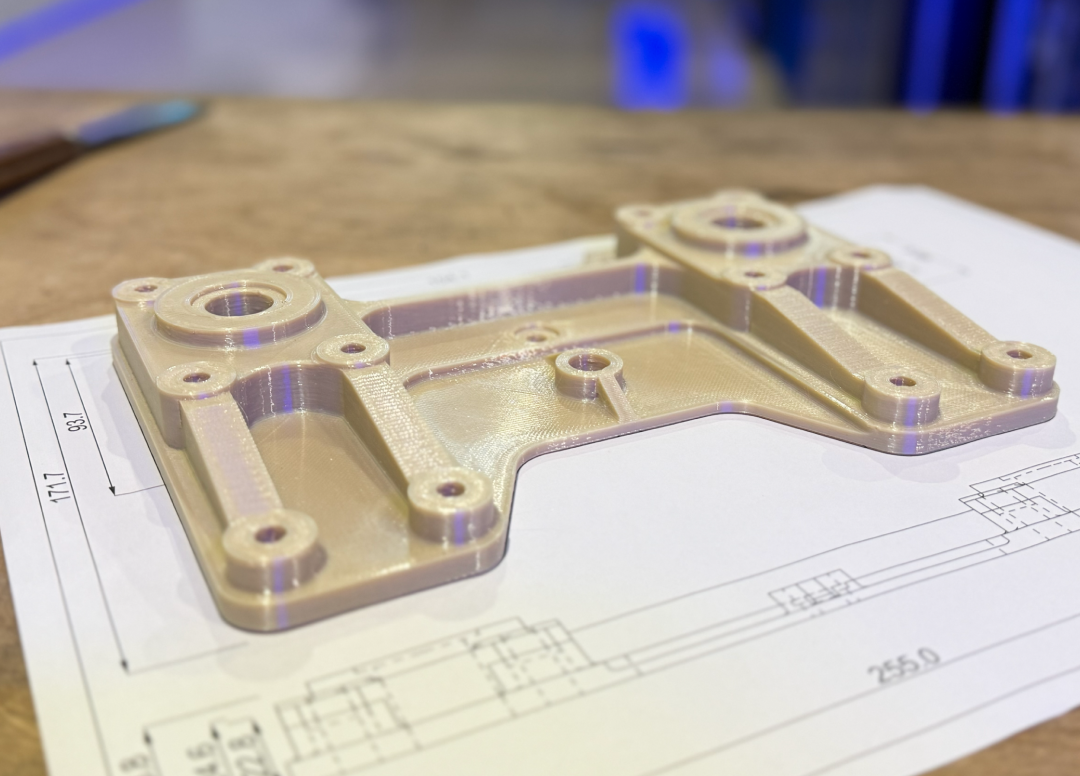

This approach becomes particularly evident in the aerospace bracket printed in ULTEM™ AM9085F, used here as a case study. Holes, seats, and functional surfaces are sensitive areas where even minimal deviations can compromise mechanical fit.

SlizeR predicts where differential contractions will occur, how they will influence the final geometry, and what compensations must be introduced to achieve nominal dimensions.

In the comparison between CAD model and printed part, the consistency is immediately clear:

large hole internal diameter (CAD: 104.1 mm / printed: 103.8 mm),

upper section length (CAD: 255.0 mm / printed: 254.5 mm)

and height (CAD: 28.8 mm / printed: 28.6 mm).

Variations on the order of hundredths confirm that the correction is not a generic adjustment, but a predictive model applied precisely and consistently.

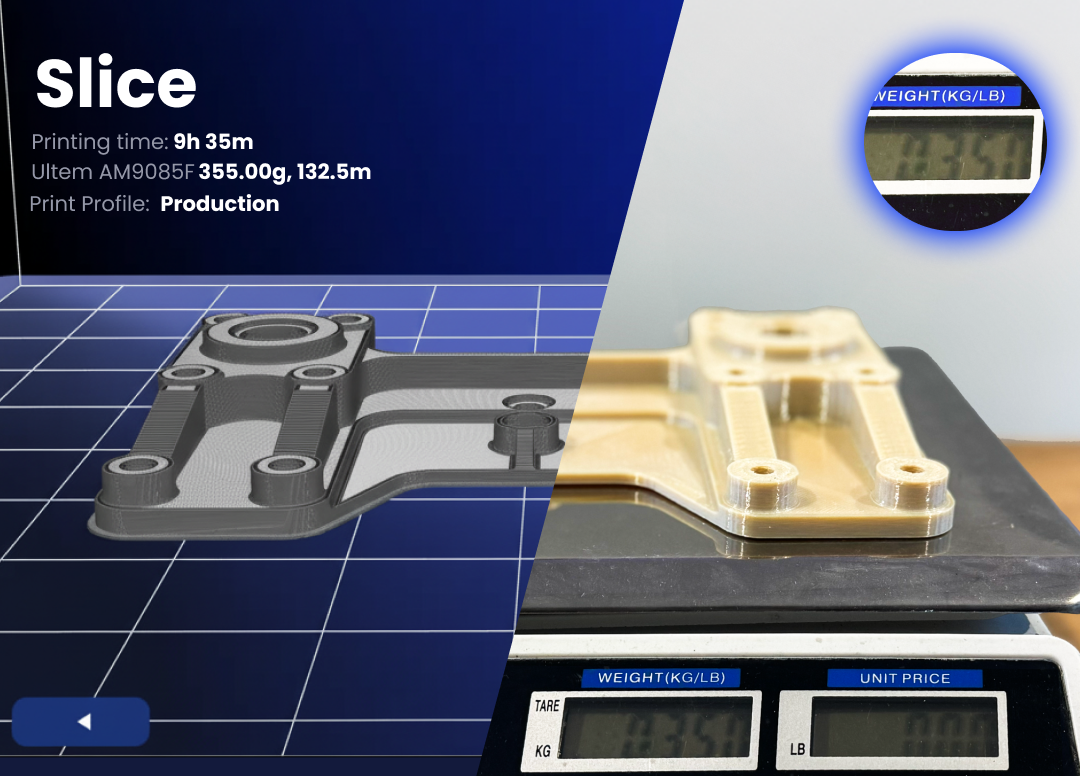

3. Accurate prediction of time, weight, and resources

Predictive engineering is not only about geometry, it also concerns planning.

SlizeR employs extrusion models, real volumes, and kinematic parameters to estimate cycle time and material usage with an average deviation of around 5% in industrial applications.

This enables more reliable management of production flows, especially when a single machine must handle multiple batches or multiple materials throughout the week.

In the bracket’s case, SlizeR’s predicted weight (355,00 g) is compared to the actual measured weight (350,00 g) during validation. This comparison shows that the software does not simply estimate theoretical volume; it also accounts for micro-variations resulting from infill parameters, actual filament density, and deposition strategies.

For aerospace applications, where every gram matters, this predictive reliability prevents waste, enables more robust planning, and enhances process control.

4. Smart Seam Generation: Engineering-Driven Surface Control

Surface quality is not a secondary aesthetic detail—it is a functional element that directly affects aerodynamics, assembly, and component durability. Within this context, SlizeR integrates Smart Seam Generation, an algorithm designed to optimize the distribution of seam lines during printing.

The function analyzes the 3D model by evaluating surface flow, thickness variations, path continuity, and critical geometries. Its goal is to determine the most advantageous placement of seams, reducing visual impact and improving perceived quality in visible areas.

In the case of the aeronautical bracket, this results in:

smoother, more continuous surfaces,

reduced scarring,

less need for post-production finishing activities.

The final result demonstrates how predictive management of extrusion paths significantly contributes to component quality by reducing the typical issues associated with start/stop zones.

5. Quality is designed upfront

SlizeR represents the shift from empirically guided printing to an engineered process in which every parameter is a verified prediction.

Part quality is no longer measured only at the end: it is calculated, forecasted, and achieved before printing even begins. All in just a few clicks.

With SlizeR, quality is not a promise, it is a calculated result.

To learn more about SlizeR’s capabilities or evaluate the integration of Roboze systems into your production workflows, we invite you to get in touch with our experts. We will be pleased to provide the information needed to support an informed decision.

)

)