From support strategies to thermal stability: what makes SlizeR different from a standard slicer

How Roboze engineering becomes software and automates crucial decisions

1. From know-how to performance

In the world of high-performance additive manufacturing, the difference isn’t just made by the material or the machine’s mechanics: it’s made by the slicing software and its ability to turn knowledge into repeatable results.

Roboze SlizeR was created with a clear objective: to embed high-performance polymer expertise and the experimental evidence gathered by the R&D and process engineering teams, transforming engineering knowledge into optimized parameters that support the operator in the most critical decisions.

Every implemented feature is validated through real testing on Roboze materials and continuous feedback from internal technical units.

The result is a slicing environment that drastically reduces human error, boosts production efficiency, and stabilizes the entire process, especially when working with advanced materials such as PEEK, Carbon PA PRO, or ULTEM™ AM9085F.

2. Adaptive Infill: density only where it’s needed

In high-performance additive manufacturing, the thickness and distribution of the infill determine the balance between mechanical strength and production time. In complex geometries, optimizing these parameters manually requires expertise, extensive testing, and careful attention to the most sensitive areas of the part.

With the Adaptive Infill function, Roboze SlizeR introduces a smarter and more controlled approach:

the user always keeps full command of the parameters, while enabling Strong Mode, which allows the algorithm to modulate infill density adaptively based on the selected value.

How it works

The user sets the base infill value.

The user manually activates Strong Mode, signaling that adaptive behavior is desired.

Once enabled, Strong Mode allows SlizeR to automatically increase infill density up to 100% in areas where the geometry requires greater support.

This ensures that the part is reinforced only where truly necessary, preventing waste of material and printing time.

Practical example

The user sets a base infill value (e.g., 20%).

Strong Mode is activated, switching the software to adaptive infill behavior.

SlizeR modulates density between 20% and 100%, increasing it in smaller sections or in areas that require higher structural robustness, as defined by the Strong logic.

Operational advantages

Print time reduction of over 30% in complex geometries.

Increased mechanical strength in delicate or highly stressed areas.

Lower risk of errors by avoiding underestimation of density in critical zones.

Full user control supported by a predictive algorithm that optimizes only when required.

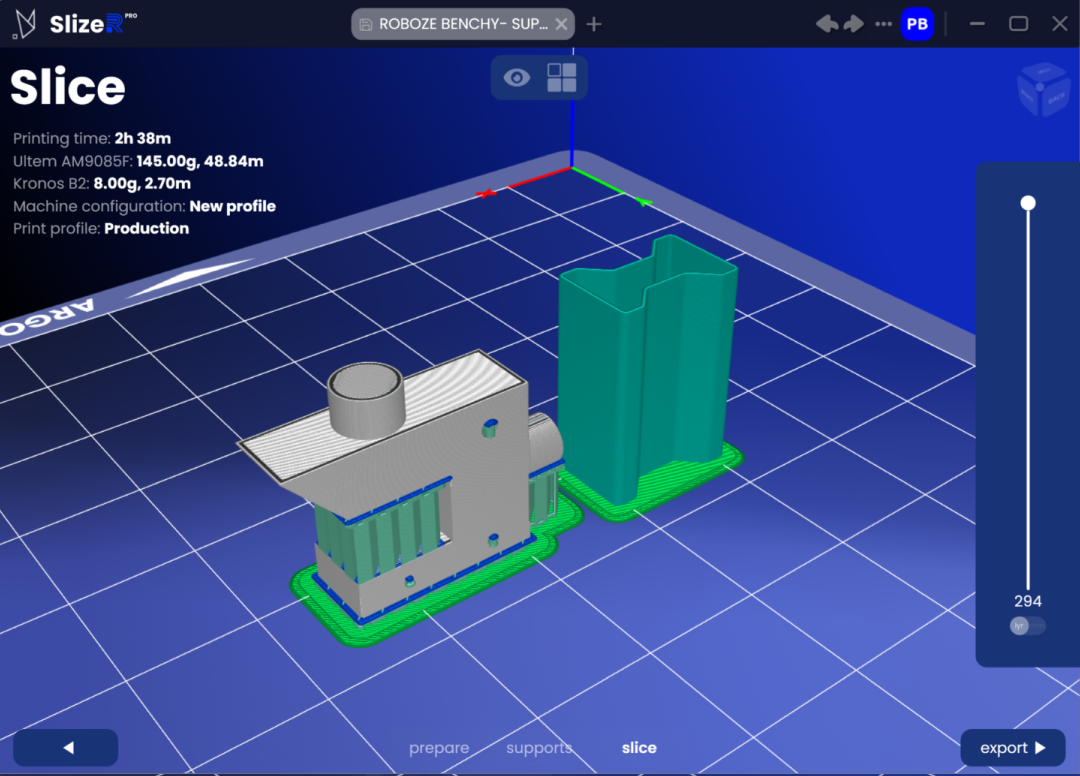

3. Cooling Tower, Intelligent Pyramid Supports, and Error Control

Dimensional stability is a fundamental requirement in industrial applications.

SlizeR integrates tools that enable operators to:

improve the quality of small geometries,

stabilize thin walls,

prevent defects caused by localized overheating,

generate complex supports in a more engineered and controlled way.

Cooling Tower

When a geometry features very small areas, each layer may not cool sufficiently before the next extrusion. In these cases, SlizeR:

calculates whether a Cooling Tower is needed,

recommends activation to the user,

still allows full manual control.

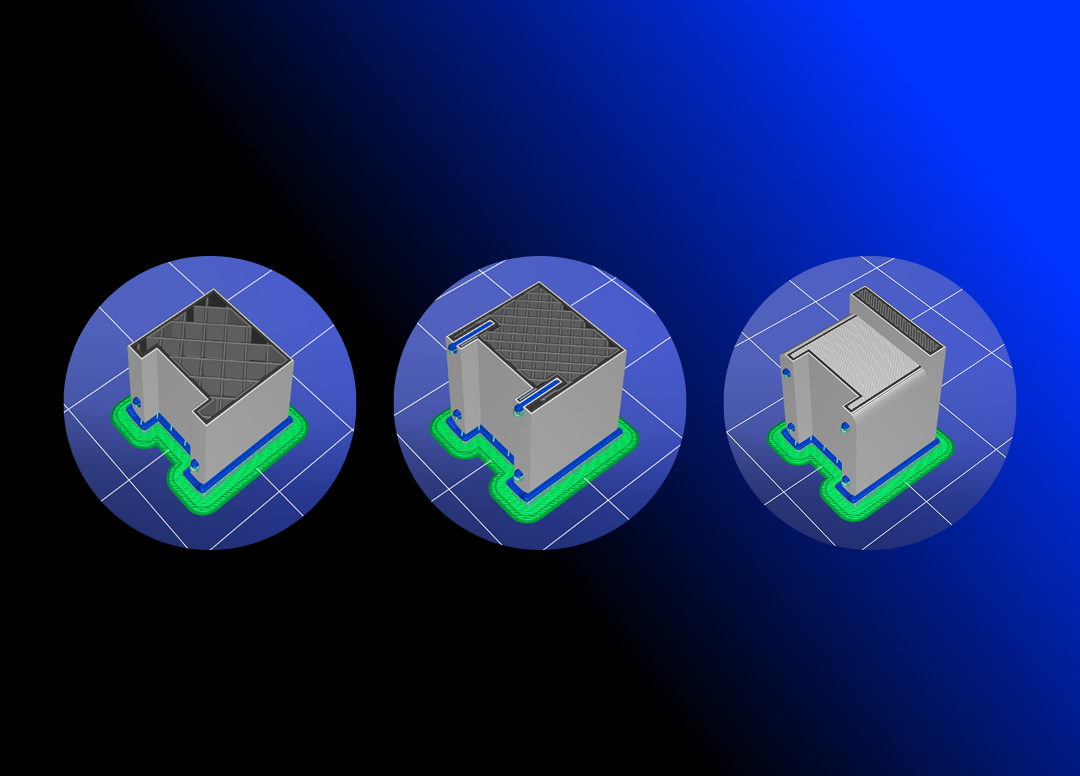

This tower (Image 1) serves as a “return point” for the nozzle, ensuring proper cooling and reducing overheating defects.

Image 1: Intelligent cooling: SlizeR generates a Cooling Tower when necessary, preventing overheating and maintaining part quality even in the smallest geometries.

Image 1: Intelligent cooling: SlizeR generates a Cooling Tower when necessary, preventing overheating and maintaining part quality even in the smallest geometries.

Intelligent Pyramid Supports: complex geometries, simple removal

Support generation is one of the most critical factors in industrial FFF printing, especially in the presence of internal cavities, undercuts, or deep overhangs.

With many software tools, supports in these zones require prolonged wall contact, making post-processing slow, difficult, and risky.

With Intelligent Pyramid Supports, SlizeR introduces a new paradigm: a structure that adapts to geometry, maintains distance from the part until the final layers, and ensures only the contact required for mechanical support.

How it works

The algorithm analyzes each surface requiring support and generates a pyramidal volume that grows from the build plane or an existing support, narrowing progressively until creating a precise contact point.

This approach:

avoids lateral adhesion to walls, even inside holes or thin sections (Image 2),

follows overhangs only where necessary, without intruding into free space (Image 3),

keeps the part cleaner and easier to finish.

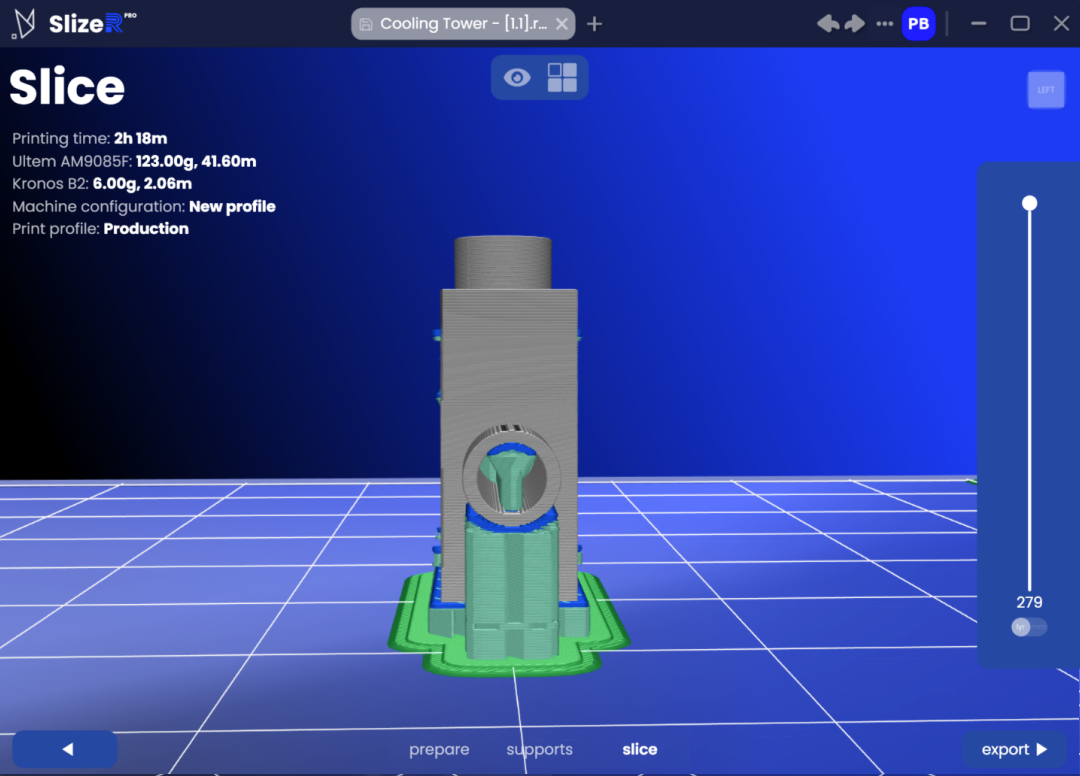

Image 2: Front view of cavity: the pyramidal support grows autonomously and avoids wall contact, expanding only in the final layers to sustain the critical surface.

Image 2: Front view of cavity: the pyramidal support grows autonomously and avoids wall contact, expanding only in the final layers to sustain the critical surface.

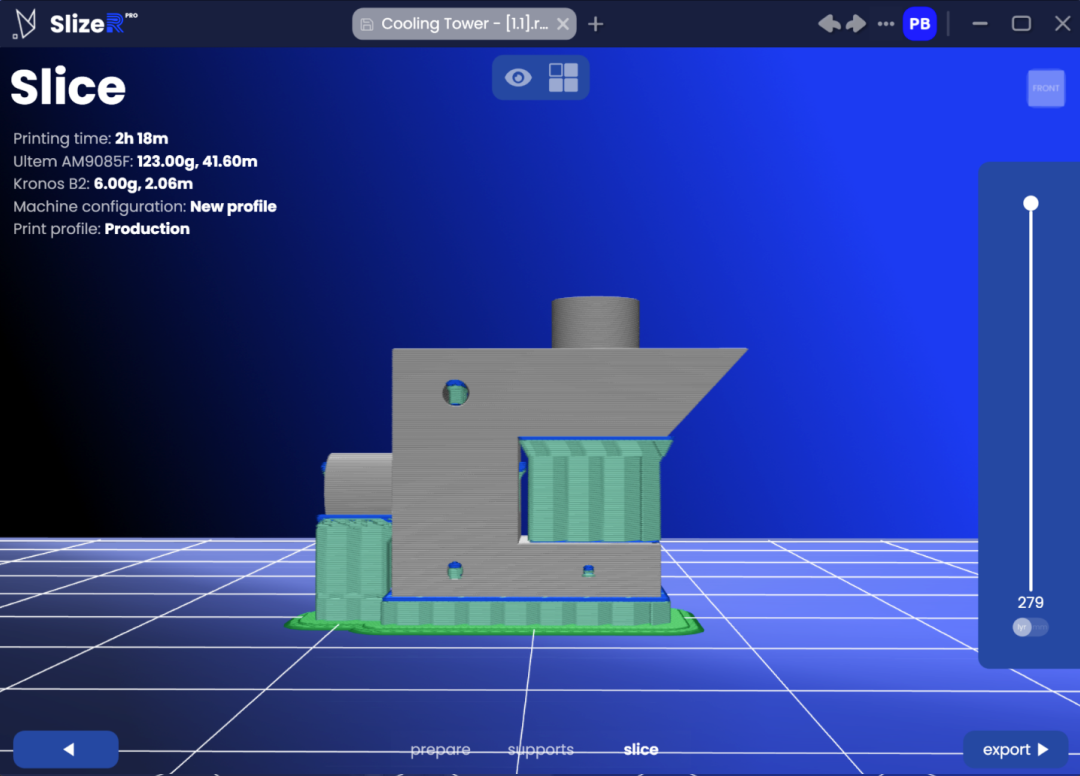

Image 3: Components with suspended features: the left overhang is supported without any vertical structure from the build plate.

Image 3: Components with suspended features: the left overhang is supported without any vertical structure from the build plate.

Collision Reduction and Layer Stability

SlizeR integrates predictive controls simulating nozzle and layer behavior in advance.

The algorithm prevents collisions by analyzing protrusions and critical toolpaths, stabilizes thin walls by modulating speed and acceleration, and reduces defects in complex geometries by optimizing thermal dissipation and print sequencing.

The result: a safer, more stable, and highly repeatable process, even under challenging conditions.

4. Software Intelligence, Guaranteed Results

SlizeR is far more than a slicing software: it is the culmination of years of research, material testing, and engineering validation by the Roboze team.

Its advanced functions enable users to:

achieve more stable processes,

reduce iterations,

shorten overall production time,

ensure repeatable and verifiable quality.

SlizeR doesn’t just prepare a print: it interprets material behavior and optimizes the final outcome already in the digital phase.

Don’t just print, optimize.

SlizeR is the difference between a good result and an engineered one.

Contact our experts today to learn more.

)

)