Designing for extreme environments: how to extend the lifecycle of industrial products

When an environment truly becomes extreme

An operating environment is defined as extreme when service conditions accelerate the natural degradation of materials, drastically reducing component lifespan if not properly designed.

Long-term exposure to high temperatures, aggressive chemicals, and mechanical loads can degrade material behavior, reducing reliability over time.

(Pacific Northwest National Laboratory, Materials in Extreme Environments, 2023).

High temperatures and continuous thermal stress challenges

In Aerospace and Energy applications, thermal stress rarely occurs as an isolated event. More often, components operate under sustained extreme temperatures or repeated thermal cycles, introducing cumulative internal stresses.

The engineering challenge is therefore not overcoming a single thermal limit, but ensuring that materials retain mechanical properties and dimensional stability over time, avoiding creep, relaxation, and permanent deformation that typically emerge only after thousands of operating cycles.

Chemical agents and aggressive environments

In many oil & gas and aerospace applications, components are constantly exposed to:

· fuels

· oils and technical fluids

· pressurized gases

· chemically active atmospheres

These conditions act silently but continuously, progressively reducing product lifecycle if materials and component architecture are not properly selected and engineered.

Vibrations and dynamic loads

Vibrations do not break a component in a single day.

They wear it down over time.

Cyclic loads, oscillations, and non-uniform stresses accelerate material fatigue, making lifecycle a design variable just as critical as initial strength.

Advanced materials and design: the foundation for extending lifecycle

When the goal is to extend product lifecycle, traditional materials quickly reveal their limitations.

This is where high-performance polymers come into play.

Materials such as PEEK, ULTEM™ AM9085F, and reinforced composites are engineered to:

· maintain long-term mechanical stability

· resist thermal and chemical degradation

· deliver repeatable performance throughout the entire lifecycle

However, selecting an advanced material alone does not automatically result in a long-lasting product.

How that material is processed is just as critical.

Designing to extend lifecycle, not just to function

In extreme environments, a component that “works” today may become a critical failure point tomorrow.

This is why design must shift from a short-term performance mindset to a lifecycle-oriented approach.

Anticipating degradation before it occurs.

Extending product lifecycle means designing while considering:

· how the material will age

· how it will respond to combined stresses

· how tolerances will evolve over time

· which areas will be most prone to fatigue

This approach reduces maintenance interventions, downtime, and premature replacements.

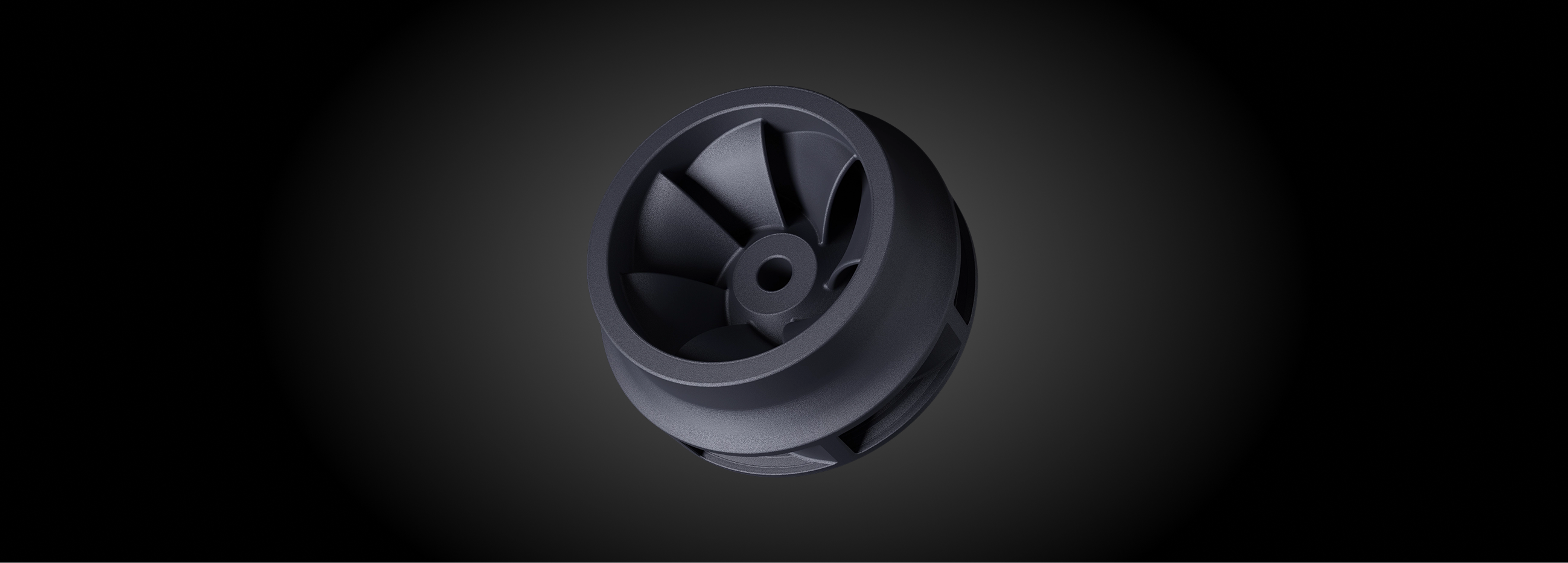

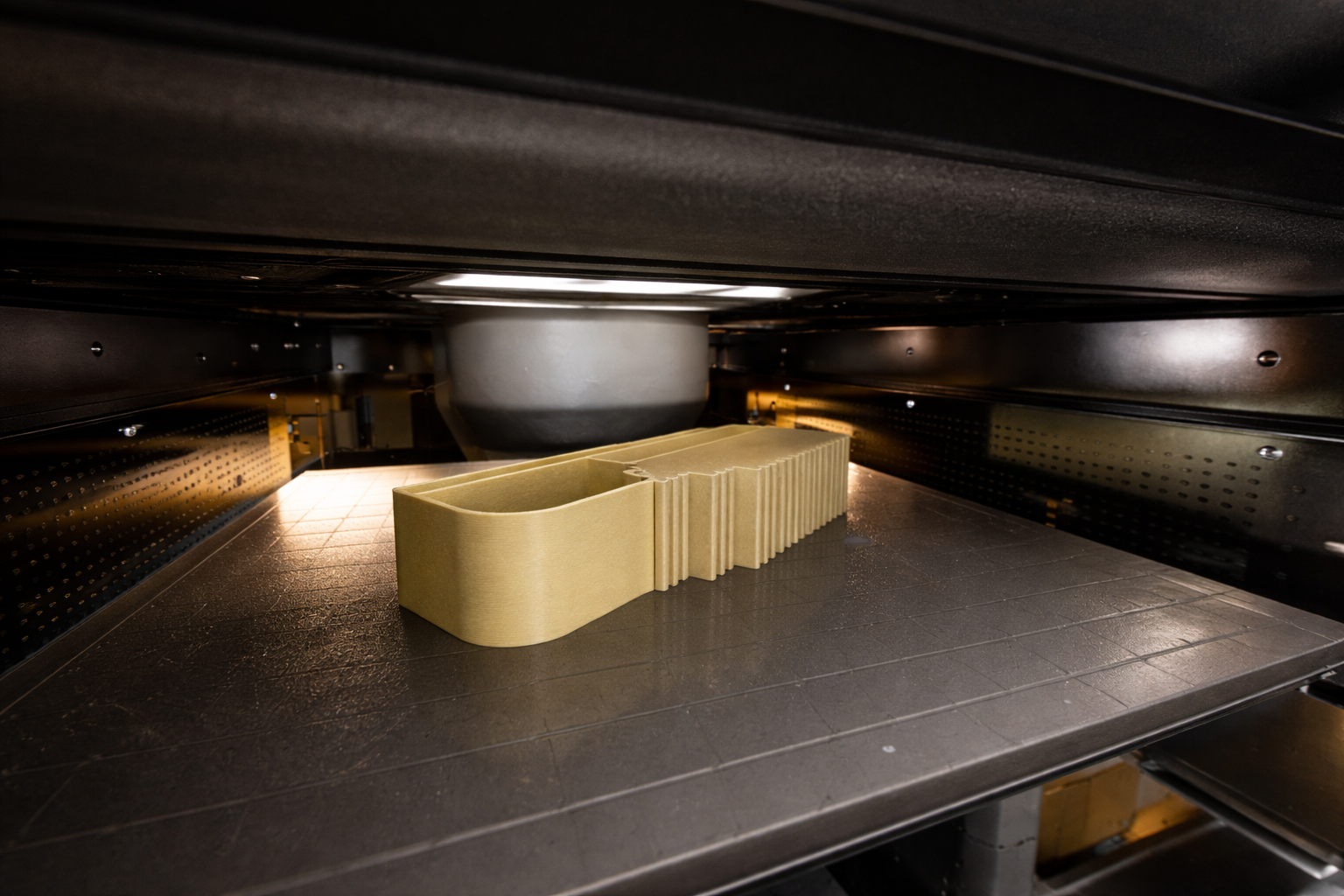

Design for Additive Manufacturing as a strategic tool

Industrial additive manufacturing enables engineers to directly address the root causes of degradation, not just the symptoms.

Through Design for Additive Manufacturing (DfAM), it is possible to:

· redistribute internal stresses

· eliminate stress concentration points

· integrate functions, reducing joints and assemblies

· design geometries that improve thermal management

In this context, additive manufacturing is not merely a production choice, but a design lever for extending product lifecycle.

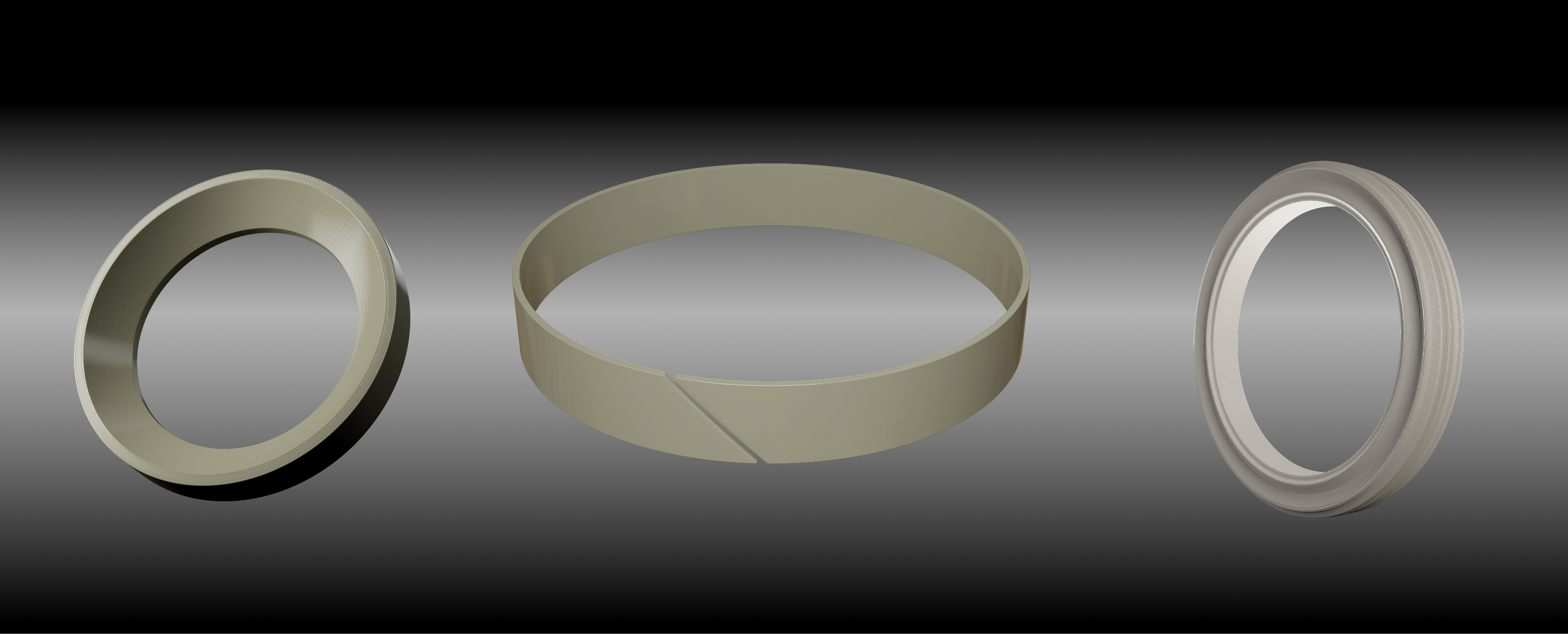

The following examples represent custom O-ring design case studies developed for Oil & Gas applications, where extended lifecycle, chemical resistance, and dimensional stability under extreme operating conditions are critical requirements.

The Roboze approach: extending lifecycle through material architecture

Roboze was founded with a clear vision: making high-performance polymers reliable even in the most critical industrial conditions.

Thanks to:

· additive manufacturing systems engineered for advanced technical materials

· strict control of thermal parameters

· process repeatability and stability

· an engineering-driven lifecycle approach

Roboze enables technical teams to design components that not only meet initial requirements, but maintain performance over time, even in extreme environments.

This allows companies to:

· reduce weight compared to metal solutions

· simplify complex architectures

· accelerate development

· increase reliability throughout the entire lifecycle

In extreme conditions, lifecycle is a design choice

In Aerospace and Energy, designing for extreme environments means accepting time as an engineering variable. Initial performance is not sufficient unless components can maintain stability, reliability, and repeatability throughout their operational lifecycle.

From this perspective, materials, geometries, and processes must be evaluated not for what they promise at the beginning, but for what they guarantee over time.

In this scenario, Roboze enables a lifecycle-oriented design approach, providing technologies that make high-performance polymers a concrete choice even for the most demanding environments. Not as a theoretical alternative to traditional materials, but as an industrial-grade engineering solution capable of meeting severe requirements throughout the entire product lifecycle.

Learn more about designing high-performance polymer components for extreme environments.

Discover the Roboze technological approach.

Sources

Pacific Northwest National Laboratory – Materials in Extreme Environments

Case studies highlighting how long-term exposure to high temperature, mechanical loads, and aggressive chemistries leads to coupled degradation mechanisms in energy and aerospace components.

https://mdpi-res.com/bookfiles/book/10849/Engineering_Materials_in_Extreme_Environments.pdf

NASA – Coupled material degradation and lifetime prediction at high temperature

Research demonstrating how interacting creep, fatigue cycles, and temperature effects reduce probabilistic lifetime strength in aerospace materials.

https://ntrs.nasa.gov/api/citations/19920011271/downloads/19920011271.pdfAIP Advances – Degradation under combined thermo-mechanical and chemical loading

Review of experimental and modeling studies showing that combined loading conditions accelerate material degradation compared to isolated stress modes.

https://pubs.aip.org/aip/adv/article-pdf/doi/10.1063/5.0235670/20260460/115317_1_5.0235670.pdfmperature

Research demonstrating how interacting creep, fatigue cycles, and temperature effects reduce probabilistic lifetime strength in aerospace materials.

https://ntrs.nasa.gov/api/citations/19920011271/downloads/19920011271.pdfAIP Advances – Degradation under combined thermo-mechanical and chemical loading

Review of experimental and modeling studies showing that combined loading conditions accelerate material degradation compared to isolated stress modes.

https://pubs.aip.org/aip/adv/article-pdf/doi/10.1063/5.0235670/20260460/115317_1_5.0235670.pdf

)

)