ARGO 500 HYPERSPEED: evaluation of repeatability and mechanical performance of ULTEM™ AM9085F according to ISO 527

The transition of Additive Manufacturing toward full-scale industrial production requires systems capable not only of delivering high mechanical performance, but, crucially, ensuring repeatability, process stability, and dimensional control. For high-performance polymers such as ULTEM™ AM9085F, these requirements are essential for qualification in aerospace, defense, and advanced mobility applications.

Within this context, a dedicated evaluation was carried out on the ARGO 500 HYPERSPEED system, engineered to combine high-speed material deposition with rigorous thermal regulation and extrusion consistency. The goal of the study was to verify intra-build repeatability and performance consistency across specimens produced in a single manufacturing session, following the ISO 527 standard testing protocol.

Methodological approach: a structured verification of printing process stability

The experimental strategy did not aim solely at determining the bulk material properties, but rather at assessing the process capability of the printing system.

Through the production of 27 ISO 527-1A specimens, the investigation evaluated geometric accuracy and consistency of the mechanical response, verifying the independence of performance from build orientation and specimen positioning within the build volume.

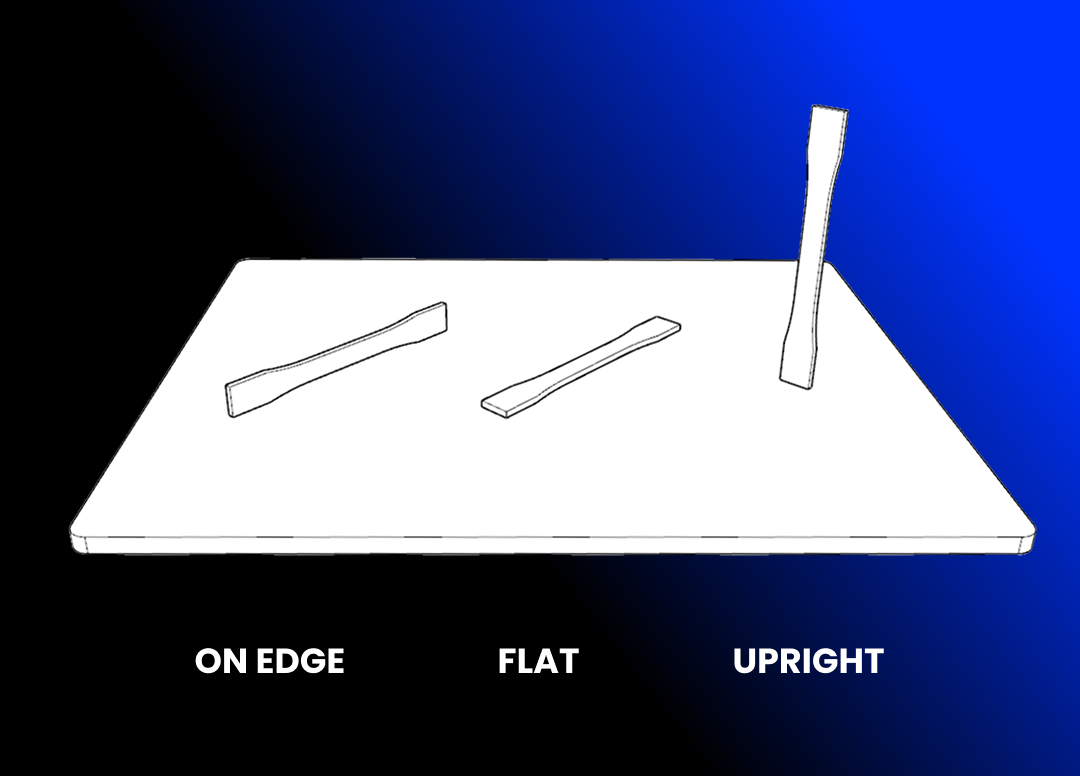

Three standard FFF printing configurations were reproduced (Figure 1), serving as a reference framework for Design for Additive Manufacturing (DfAM) and enabling correlation between geometric choices and expected material behavior:

Upright (UR) – 12 specimens. The most critical orientation under tensile loading, directly stressing interlayer adhesion.

Flat (XY) – 11 specimens. Features a ±45° deposition pattern, closely mirroring conditions found in real components, especially in bottom layers, top surfaces, and skins, where this infill scheme influences mechanical behavior.

On-edge (OE) – 3 specimens. A lateral orientation providing insight into peak tensile performance thanks to strands aligned with the load direction. It also reflects the behavior of thin walls characterized by parallel filament arrangement.

Figure 1. Diagram of the three FFF printing orientations.

Figure 1. Diagram of the three FFF printing orientations.

The consistency of the results is guaranteed by an industrial-grade production process.

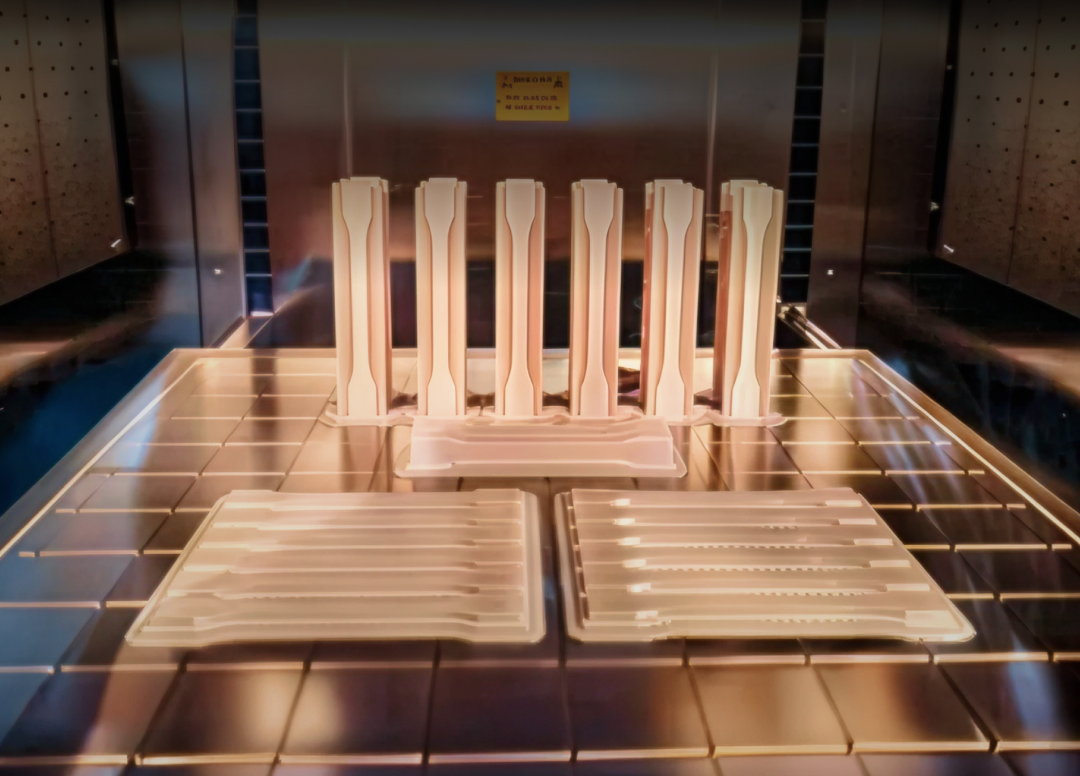

All specimens were manufactured within a single production session (Figure 2), ensuring maximum batch homogeneity. Process stability was validated through continuous monitoring of every critical input, from compressed air pressure to humidity control within the dryer.

Special attention was dedicated to thermal management: extrusion temperature was continuously monitored, while the chamber temperature was set and maintained near the material’s glass transition (Tg), creating the ideal thermal environment for deposition.

Figure 2. ISO 527 specimens freshly printed in the ARGO 500 HYPERSPEED build chamber, with Upright samples in the background and Flat/On-edge in the foreground.

Figure 2. ISO 527 specimens freshly printed in the ARGO 500 HYPERSPEED build chamber, with Upright samples in the background and Flat/On-edge in the foreground.

The adoption of ISO 527 for specimen geometry and test speed (1 mm/min) ensures comparability with existing literature on high-performance polymer materials. While the standard does not evaluate additive process repeatability, it provides a recognized framework for benchmarking mechanical behavior.

The methodology used in this campaign highlights not the performance of an individual specimen, but the consistency of production under real operational conditions. Specifically, the approach:

evaluates system stability over an entire build,

measures intra-build repeatability rather than isolated sample behavior,

verifies mechanical consistency across three distinct orientations.

These elements collectively assess the degree of process control achieved by the system, without representing qualification criteria or regulatory requirements.

In summary, the objective was not to demonstrate “what ULTEM™ AM9085F can do,” but rather how ARGO 500 HYPERSPEED maintains consistency, stability, and repeatability within a continuous production cycle, key attributes for industrial adoption.

Mechanical performance: intra-build consistency and controlled anisotropy

Tensile test results confirm mechanical behavior aligned with expectations for a high-performance amorphous polymer processed via FFF:

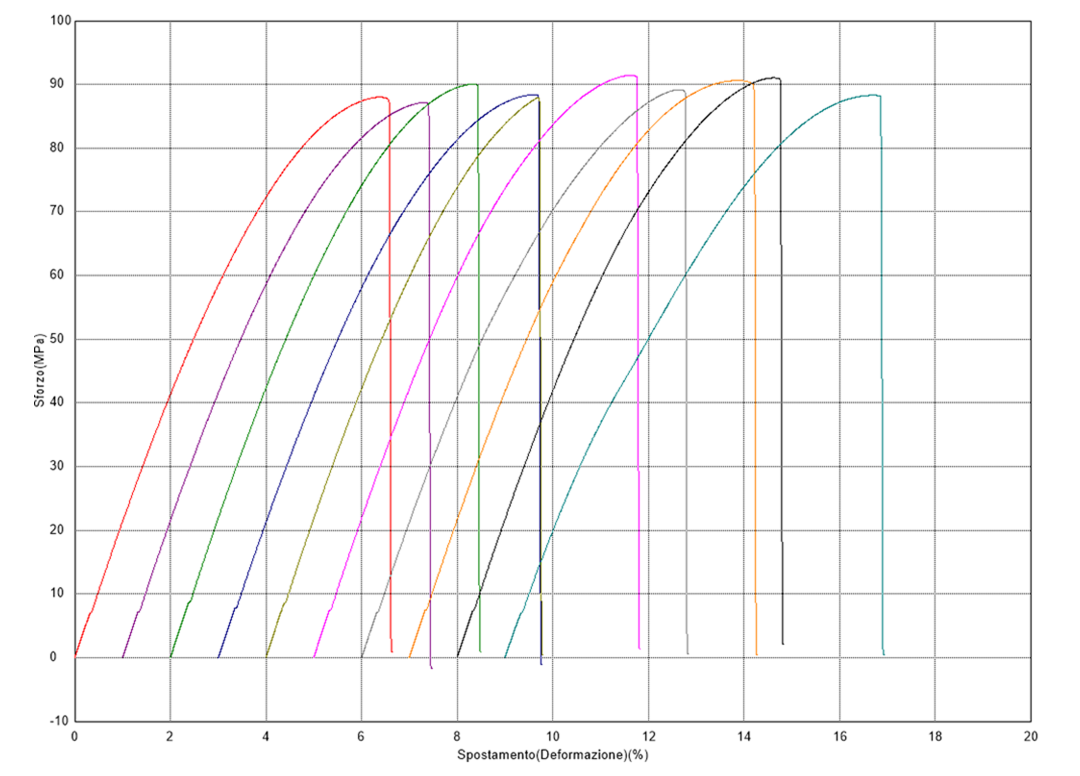

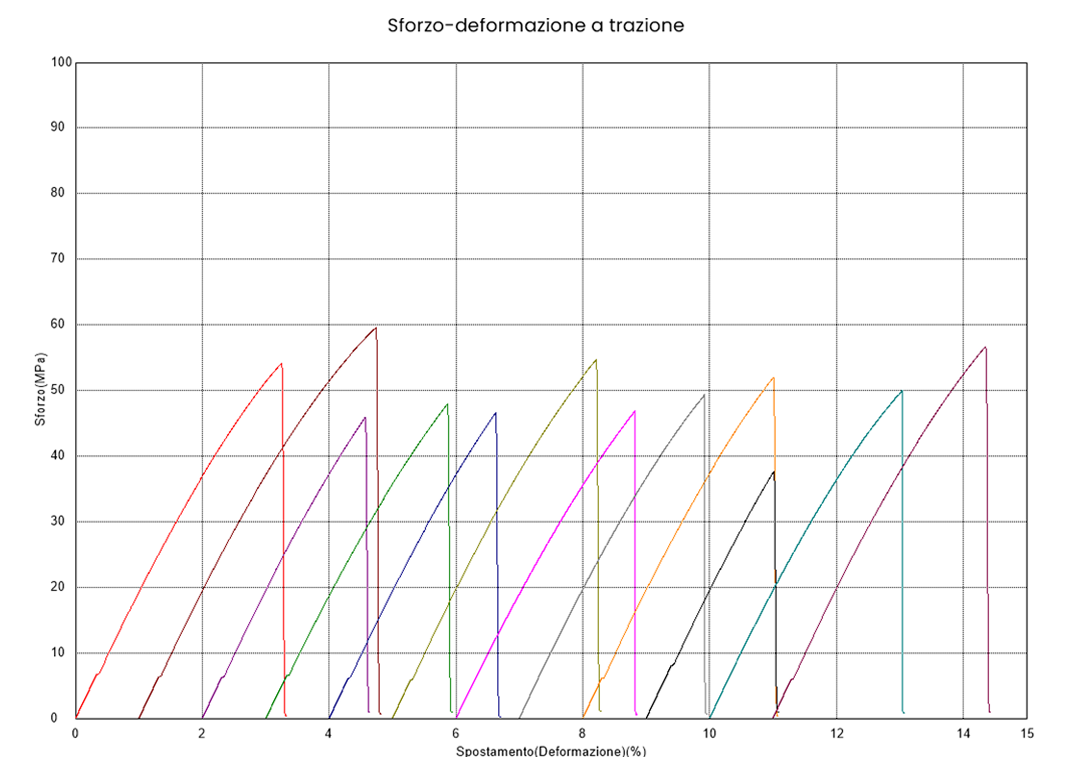

XY (Flat): 86.94 ± 7.61 MPa – Chart 1

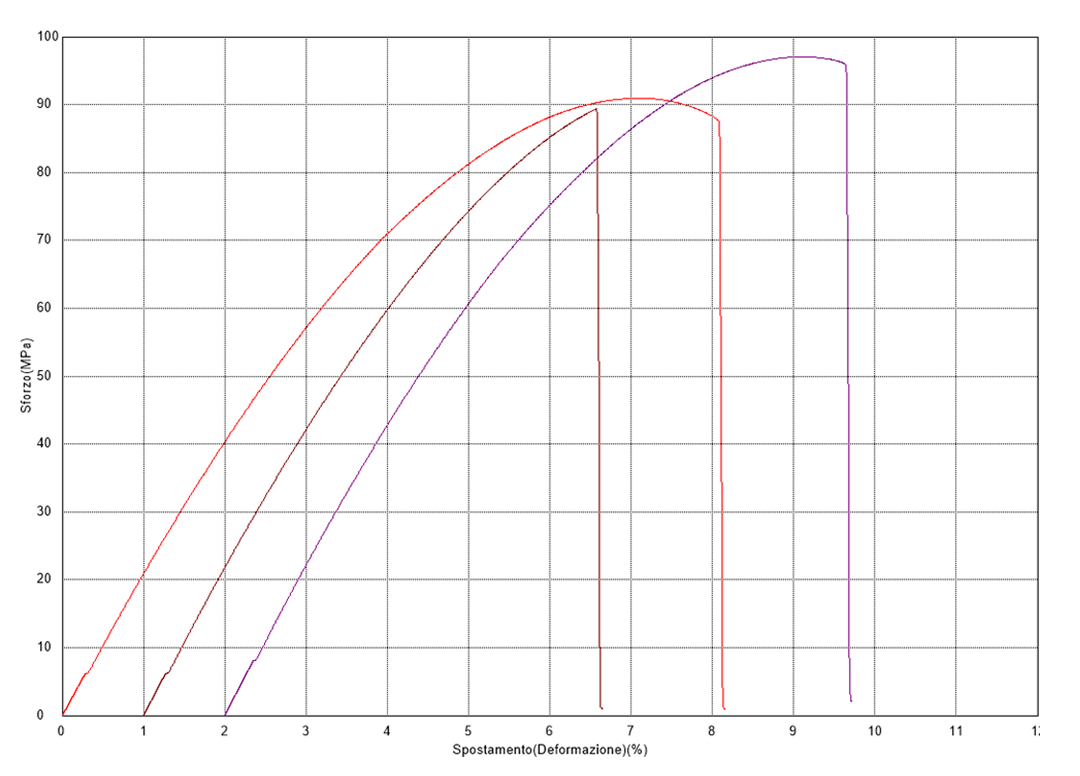

OE (On-edge): 92.45 ± 4.03 MPa – Chart 2

UR (Upright): 51.86 ± 4.76 MPa – Chart 3

Chart 1. Stress–strain curves for Flat (XY) specimens

Chart 1. Stress–strain curves for Flat (XY) specimens

Chart 2. Stress–strain curves for On-edge specimens

Chart 2. Stress–strain curves for On-edge specimens

Chart 3. Stress–strain curves for Upright specimens

Chart 3. Stress–strain curves for Upright specimens

Statistical analysis of the 27 specimens highlights the robustness of the process. Measured standard deviations, 4.03 MPa for OE, 4.76 MPa for UR, and 7.61 MPa for XY, demonstrate consistent repeatability within each orientation.

Differences observed across orientations reflect the expected anisotropic profile of FFF materials; however, anisotropy is effectively managed. Thanks to precise process control, the variation in mechanical properties along the vertical direction (UR) remains below 40%, significantly lower than the 50–60% reductions commonly documented for non-optimized systems or parameter sets.

Discussion: correlating process stability and material behavior

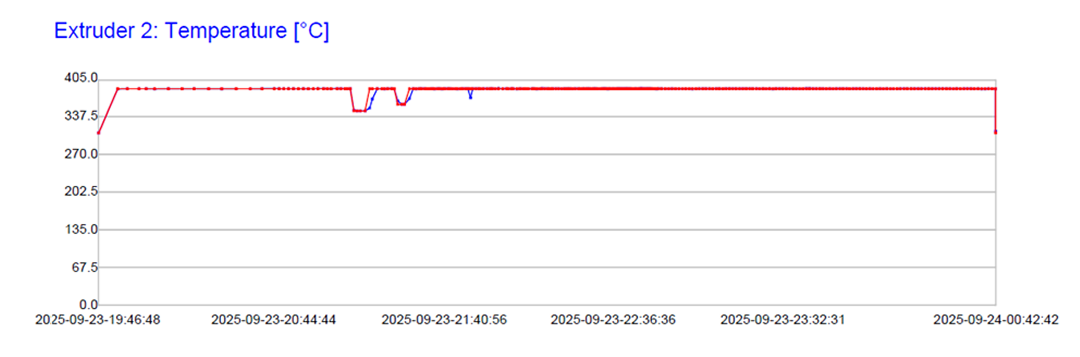

The three monitored variables, extrusion stability, filament humidity, and thermal management via SlizeR, show a direct correlation with uniform mechanical properties.

1. Extruder Stability

The extruder temperature profile recorded in the PrintLog (Chart 4) shows stable behavior throughout the entire build, with no significant deviation from the setpoint. Such thermal stability is essential to ensuring consistent melt viscosity and repeatable interlayer interactions.

Chart 4. Temperature trend of extruder 2 from machine PrintLog.

Chart 4. Temperature trend of extruder 2 from machine PrintLog.

2. Filament humidity control (Dew Point < −40°C)

The process was conducted with dryer‐conditioned air maintained at a dew point < −40°C, effectively minimizing residual moisture during extrusion.

Low humidity reduces the risk of micro-porosity, melt instability, and surface defects, contributing to consistent interlayer adhesion and mechanical performance.

3. SlizeR and predictive thermal control

SlizeR, developed specifically for the Roboze ecosystem, enables controlled definition of process parameters for each material, ensuring that the system operates with settings optimized for geometry and deposition strategy. This machine–software integration reduces variability in early layers and maintains material deposition uniformity throughout the entire build.

Together, these factors make the platform suitable for production environments where traceability and repeatable quality are non-negotiable.

Conclusions: a platform engineered for production, not just prototyping

The ISO 527 evaluation demonstrates that ARGO 500 HYPERSPEED can:

maintain geometric consistency among specimens built in a single build, with dimensional variations remaining within the measured ranges for all three orientations;

ensure mechanical uniformity within each orientation, with limited standard deviations across tensile strength, Young’s modulus, and elongation at break;

produce ULTEM™ AM9085F components exhibiting consistent mechanical behavior both within the build and at different points in the build volume, aligned with the verified operating conditions;

deliver thermal stability and overall process consistency.

These results provide a solid technical foundation for adopting the platform in industrial contexts where process reliability and repeatable quality are essential for producing functional parts.

)

)