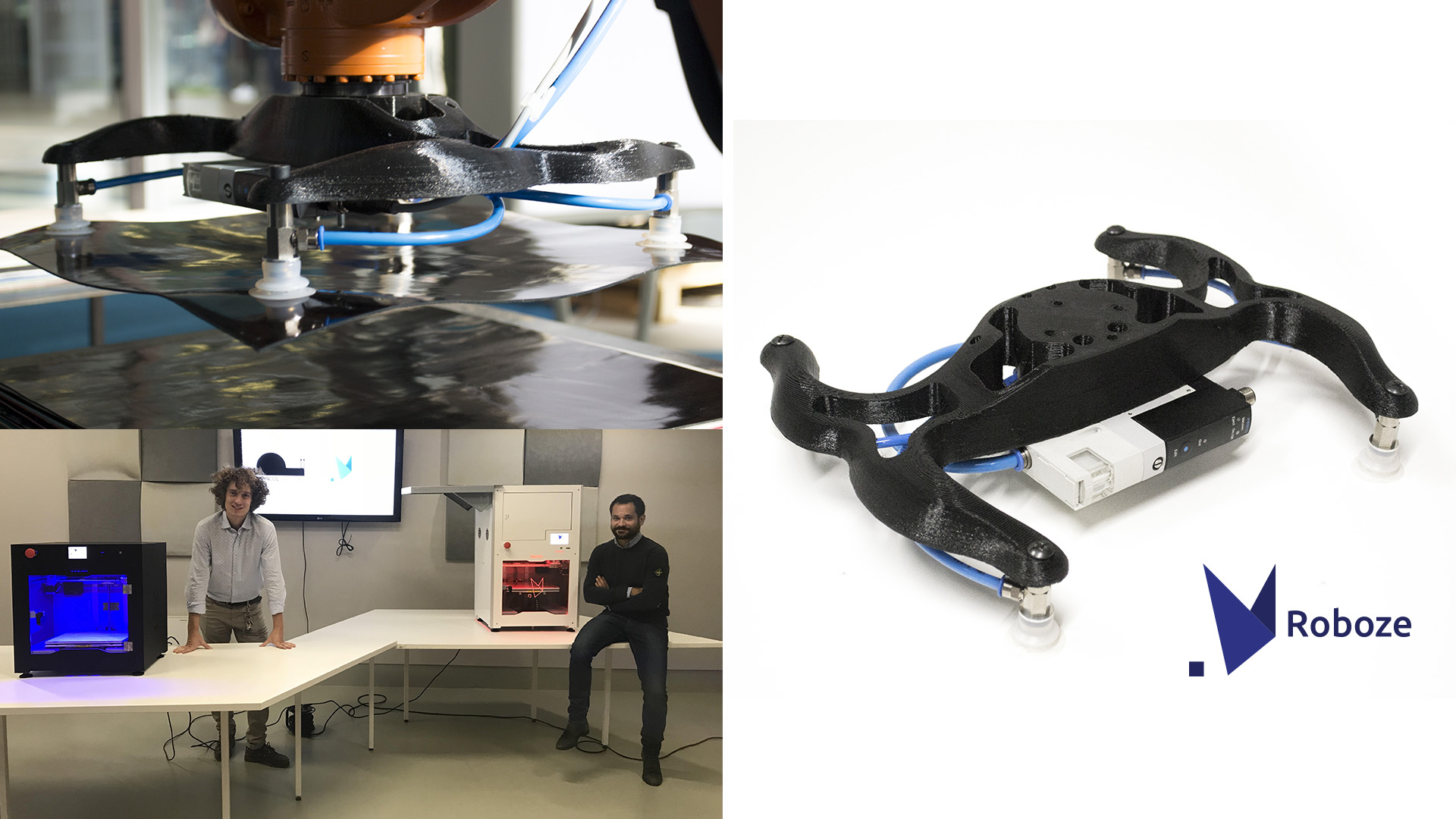

CARACOL AND ROBOZE FOR EXTREME APPLICATION additive manufacturing

Caracol Factory, department of Caracol Studio offering prototyping and manufacturing services with the most sophisticated additive manufacturing technologies, chooses Roboze to respond to the emerging demand for finished parts in high performance materials.

The two companies have recently carbon fiber reinforced polyamide, for a specific application handling soft materials, obtained thanks to the combined work between a pneumatic gripping system and a 6-axis robotic system, designed and produced by Caracol Studio.

The component was digitally designed and manufactured with the Roboze One 3d printer to best meet customer needs, realizing the design based on the forces involved, the required material and the expected manufacturing technique, in order to maintain the lightest weight possible.

O date, 3D printing remains the only manufacturing technology capable of responding to this particular need by an increasingly dynamic and demanding market.

The project - among others - required the use of a mechanically performing material: the choice fell on Carbon PA, a carbon fibre reinforced polyamide. This approach, in addition to being cheaper than traditional methods, has allowed the customer to receive a fully functional piece with a contemporary and attractive design created specifically for the non-standard processing required, significantly lighter and able to increase the processing speed of the robot, and overall productivity. Another way to do it simply does not exist.