3D Printing and production of end-use parts for industry

With additive manufacturing you can get:

- An optimized supply chain with fast reaction times

- Reduced production costs and waste

- Final components with increased performance

With Roboze 3D printing technology you can make the most of this opportunity.

Industrial 3D printing, how to meet production challenges and generate profit?

Companies take care of their competitive advantage every day by investing in the production of prototypes, innovative products and functional parts, in order to ensure high quality standards. Roboze 3D printing technology allows you to meet the challenges of the world of industrial production, as it guarantees an increase in profits and the resolution of some problems, let's see together how.

Benefits of Roboze industrial 3D printing solutions

Optimize Supply Chain and Production Processes

A company's supply chain is its backbone. With Roboze 3D printers, it is possible to achieve smoother processes and ensure a reduction in the inconveniences that can occur, as well as to concretely reduce lead times, with lower inventory costs.

From physical to digital warehouse

Having with 3D printing the possibility of producing individual components with very low waiting times and at low cost, it becomes reasonable to integrate the physical warehouse with a digital inventory containing the three-dimensional models of the spare parts. In this way, companies can design their product centrally and have parts manufactured on site, whenever and wherever needed, mitigating risks and costs related to inventory management.

Small batches production

Companies often face demands for small production batches, indicatively affecting economies of scale. With the Roboze Production series, small production batches can be realized while maintaining low costs and operating times, but most importantly, is it possible to produce only what is needed at the right time, thanks to 24/7 production runs with maximum efficiency and control.

Customized production

In a constantly changing market, unpredictable customer requests force companies to rethink their offer and internal structure, accelerating the development of new products. With traditional processes it is not possible to promptly meet this demand. With Roboze 3D printing you can better manage situations of uncertainty and criticality, avoiding that unforeseen events generate costs that could significantly affect the entire company system.

From Traditional Manufacturing to Additive Manufacturing

In traditional manufacturing, a part is processed in several departments because it must be cut, milled, welded, polished, assembled. Therefore, some steps must necessarily be outsourced. With Roboze 3D printers you can create an ecosystem completely focused on the precision, repeatability and control of the printing process, in a completely new way, reducing time and avoiding the waste of precious resources. Consequently, human resources can be employed in different tasks for greater business optimization.

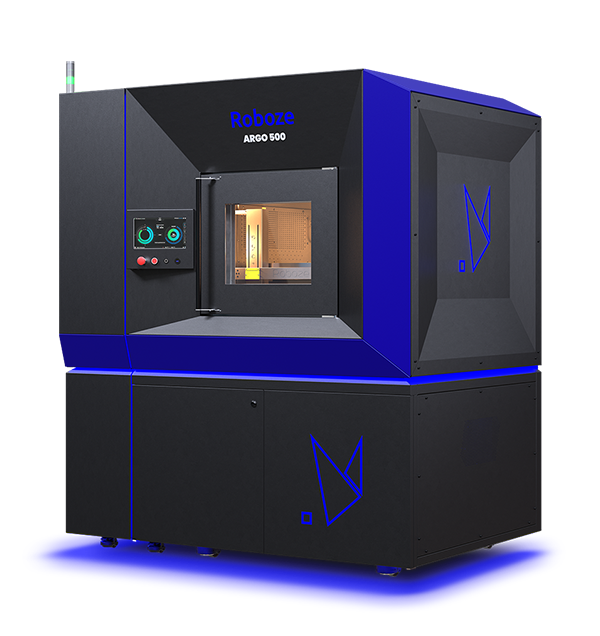

Why is Roboze industrial 3D printing unique?

- Patented Beltless movement for a mechanical positioning accuracy of less than ± 10 μm and a cumulative error close to zero;

- Roboze Heated Chamber: a heated, homogeneous and controlled work environment that guarantees quality and repeatability over time;

- Dual extruder system for high viscosity polymers, which allows to increase the complexity of the parts and the productivity, reducing the post-processing times;

- 3D printing on par with conventional methods such as CNC machining and injection molding, in terms of consistency, repeatability and process control.;

- Technical polymers and composite materials which, thanks to their mechanical, thermal and chemical properties, enable new extreme applications and metal replacement.

Grow your business with Roboze industrial 3D printers

Roboze industrial 3D printing systems are a valuable tool for integrating traditional production, as they allow you to produce small customized batches and reduce costs and delivery times for finished products. Increased competitiveness, improved corporate reputation, productivity and increased profits are direct benefits experienced by companies that have opened up to Roboze innovation in response to technological acceleration and competition on a global scale.

Discover the benefits for your company!

Competitive advantages in different sectors

Improve the efficiency of your supply chain

The world of manufacturing is undergoing a drastic shift, as it is giving way to custom manufacturing to meet consumer demands. For this, it is vitally important to have suitable and customized tools to optimize processes in each factory, taking advantage of the freedom in design and production, offered by Roboze additive manufacturing systems. By combining these advantages with high-performance materials and guaranteed repeatability of the printing process, it is possible to create perfectly customized tools, fixtures, and support structures for every need.

Produce for clean energy

As the world's demand for energy increases and in an ever-changing economic scenario, the energy sector faces new challenges. To meet consumer demand, it becomes necessary to limit shutdown times as much as possible. At the same time, Roboze 3D printing technology is helping global manufacturers in the technological transition to clean energy sources through the use of high-performance materials, efficient production methods, and warehouse dematerialization resulting in cost and emission optimization.

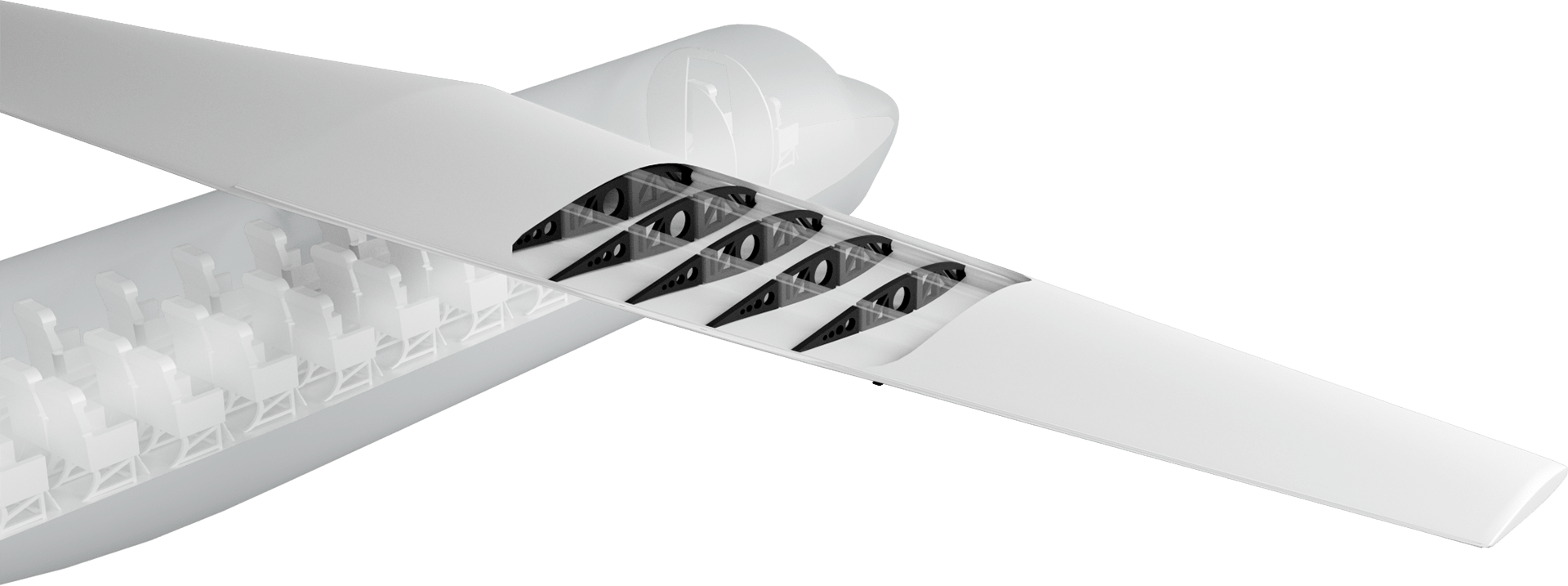

Reduce weight and increase payload

The aerospace industry, with a focus on the New Space Economy, has accelerated the adoption of 3D printing as a method of producing finished parts. So currently, additive manufacturing is pushing the boundaries of what was thought possible. Roboze 3D printing technology for super polymers and composite materials addresses the extreme needs of the aerospace industry to reduce weight, increase efficiency, and replace metals, with the goal of supporting the exploration of new solutions in orbit.

They have already choosen Roboze

Why are polymer-based materials replacing metals?

The plastics industry has made great strides in recent years by developing super polymers and composite materials that allow the production of strong and lightweight parts to replace metals.

Today, these polymers are revolutionizing various sectors: from aerospace to the transportation, where lightness means better performance, to the chemical and energy industries, where a polymer capable of working in difficult environments and at high temperatures can significantly reduce the need for maintenance.

According to the Global Metal Replacement Sales Market Report 2021, the global metal replacement market was valued at $109 billion in 2020 and will reach $170 billion by the end of 2027, growing at a CAGR of 7.2% from 2022 through 2027.

More and more companies are looking to 3D printing associated with these materials as a valuable tool for complementing traditional manufacturing, in order to produce small, custom batches that allow reduced costs and lead times for their customers.

Metals:

- subject to corrosion

- heavy weight

Polymers:

- thermal and electrical insulation, acoustic; chemical and corrosion resistance

- reduced weight and workability

The era of Metal Replacement has begun

The use of high-performance polymers and composites has made Metal Replacement possible in industrial production. Roboze 3D printing technology makes the most of this opportunity.

Who is Roboze?

Roboze designs and manufactures the world's most accurate 3D printers to produce parts with composite materials and super polymers to replace metals in industries with extreme working conditions. The main objective is to shape a new paradigm in digital production through a complete range of advanced 3D printers developed with the collaboration of the best world players, bringing Additive Manufacturing closer to the standards of traditional production.

Through its global manufacturing as a service network for the production of parts on demand and just in time, the Roboze 3D Parts division allows companies to reduce costs and time by shortening the steps of their supply chain and digitizing their inventory.