Roboze Plus PRO

The first step in high performance additive manufacturing

The first step in production for super polymers

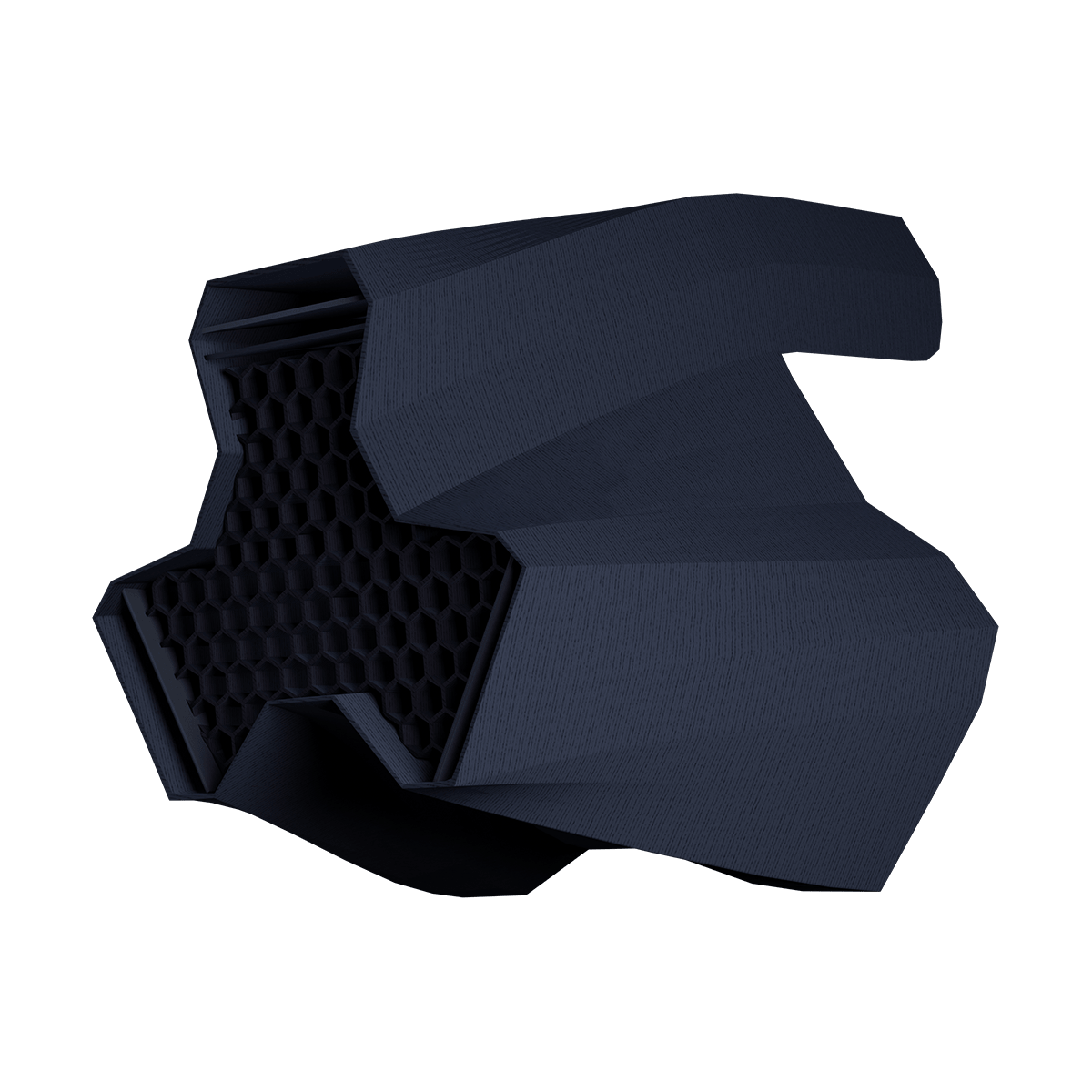

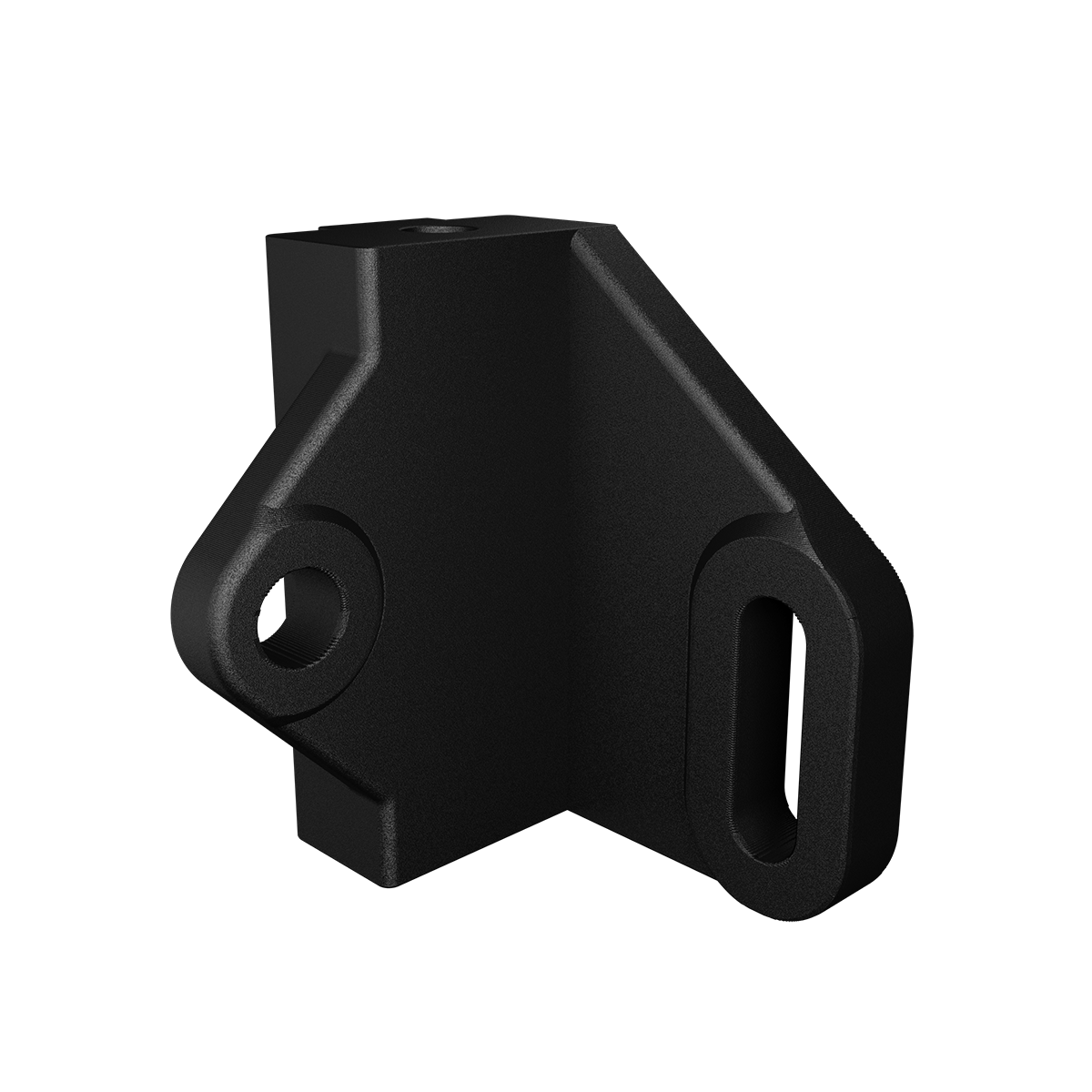

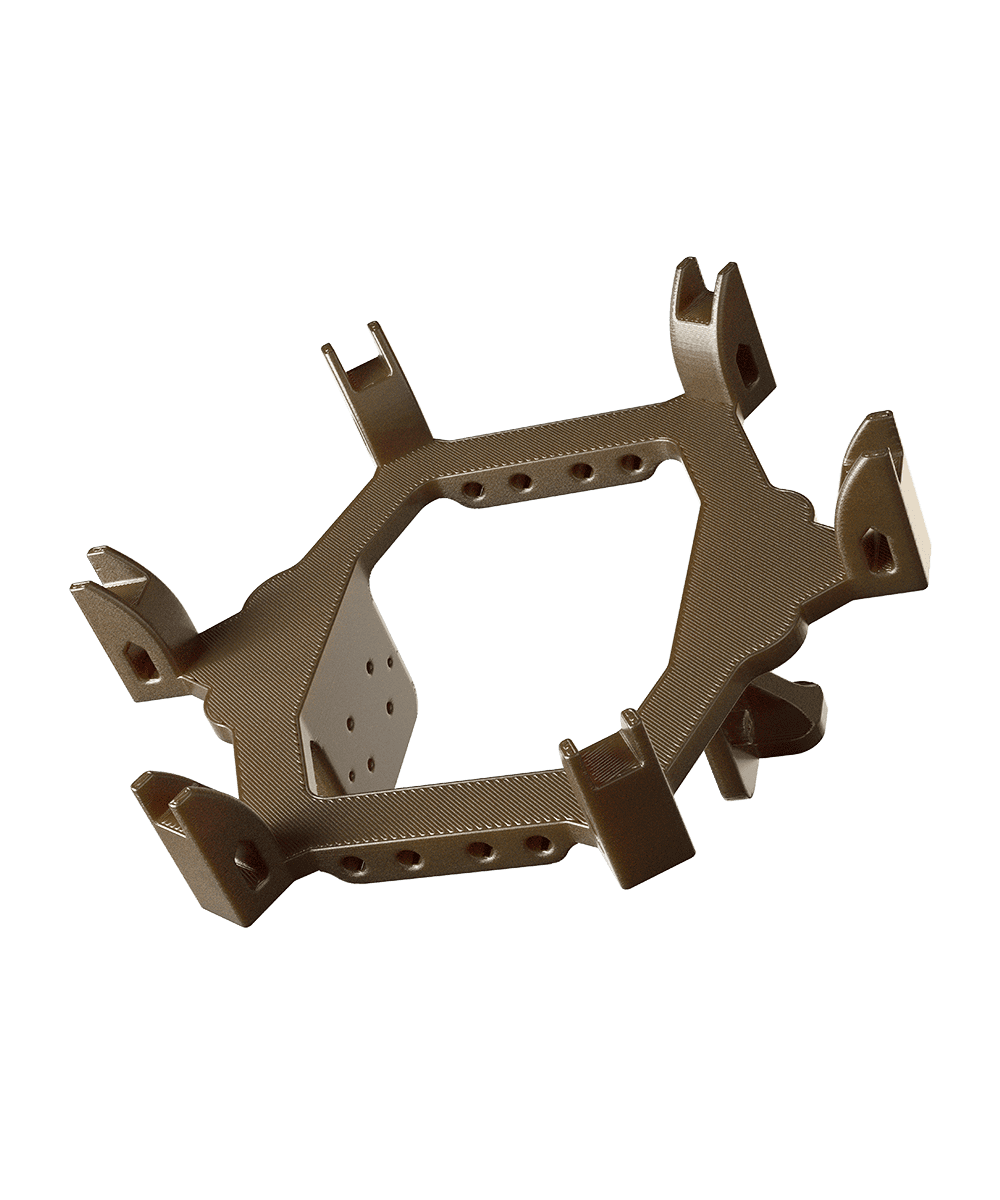

Produce functional parts in super polymers and composites

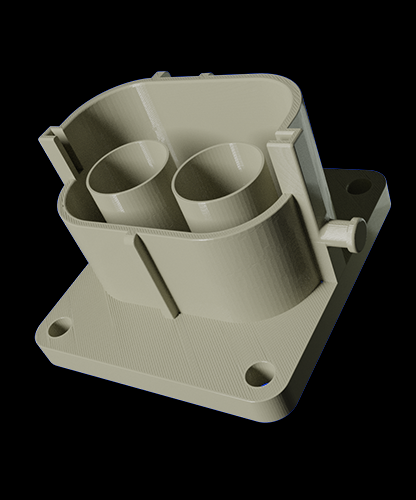

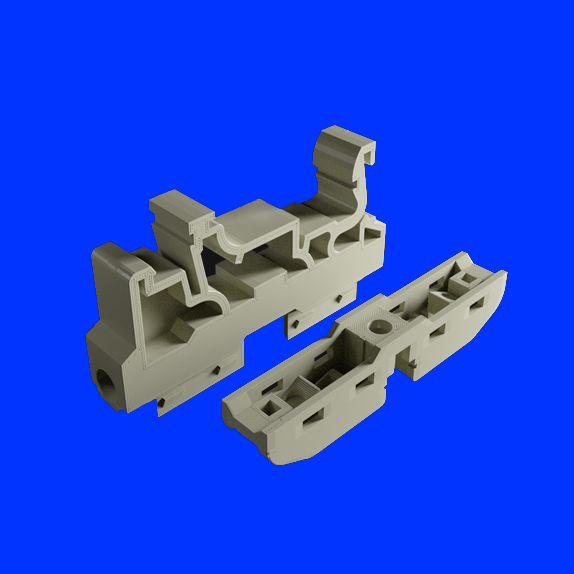

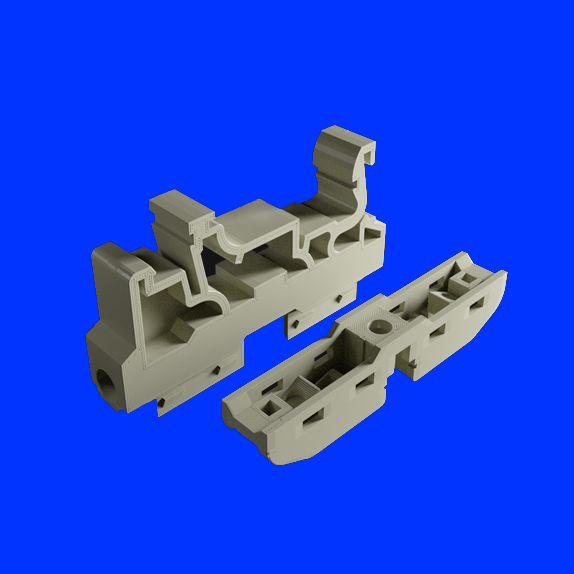

Ultra-detailed PEEK, Carbon PEEK and ToolingX CF components

Maximum flexibility when it comes to super polymers and composites! The strong specialization of Roboze and the new UltraQUALITY Prometheus 3D printing profile, today allows you to obtain functional parts with an unmatched print quality.

New high performance materials

The PRO series widens the application opportunities thanks to the new Roboze PEKK and ToolingX CF materials. Roboze Plus PRO is the most complete 3D printing professional solution designed to increase the value creation of your company and generate new competitive advantages.

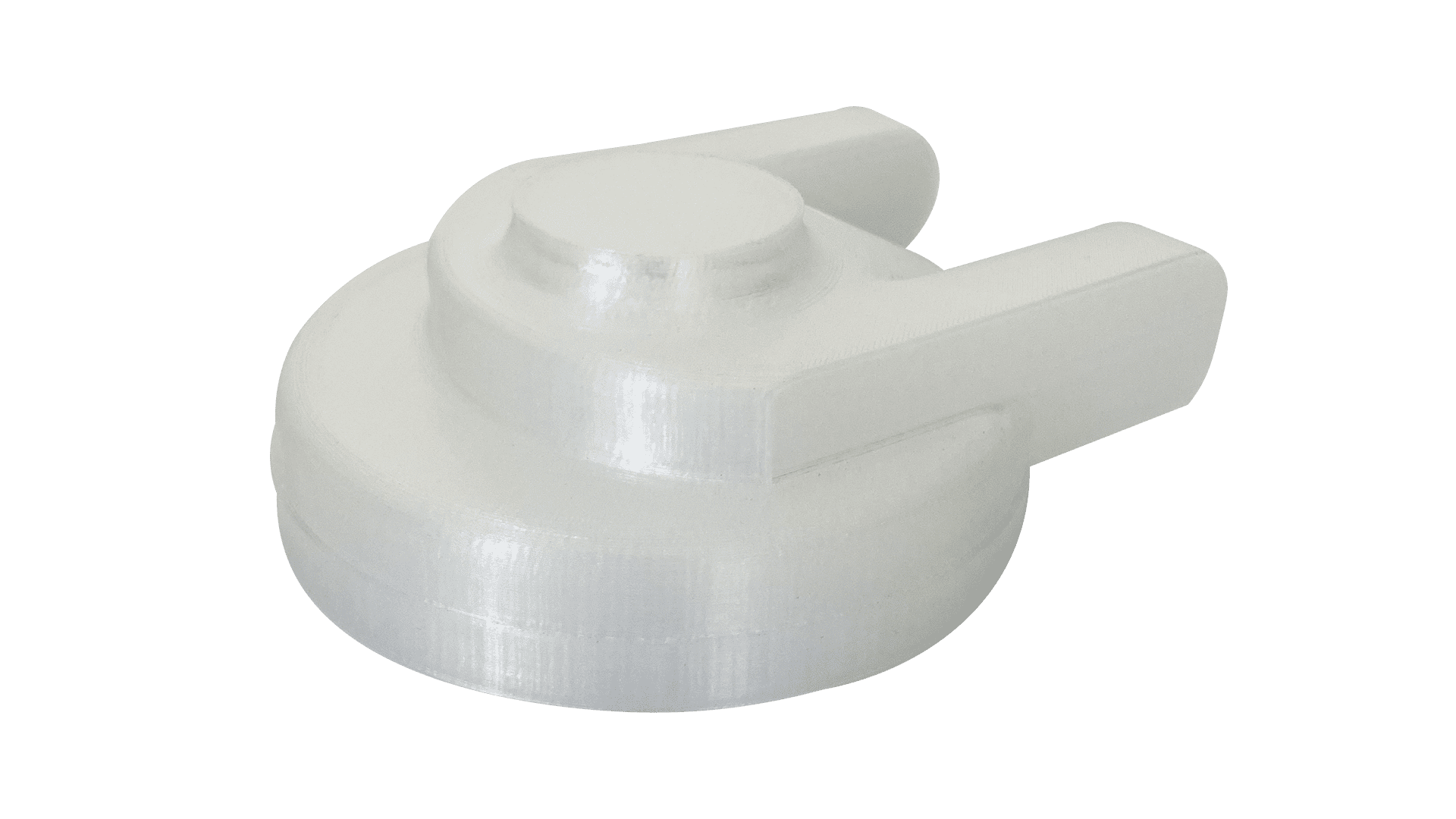

Prototypes and equipment in half the time

The UltraFAST Prometheus profile implemented for Carbon PA PRO, composite with carbon fiber, and ULTRA-PLA, special PLA to support the concept validation phase, doubles the printing speed of these parts compared to other similar solutions in the market.

Combination of efficiency and speed

Technology developed on process needs

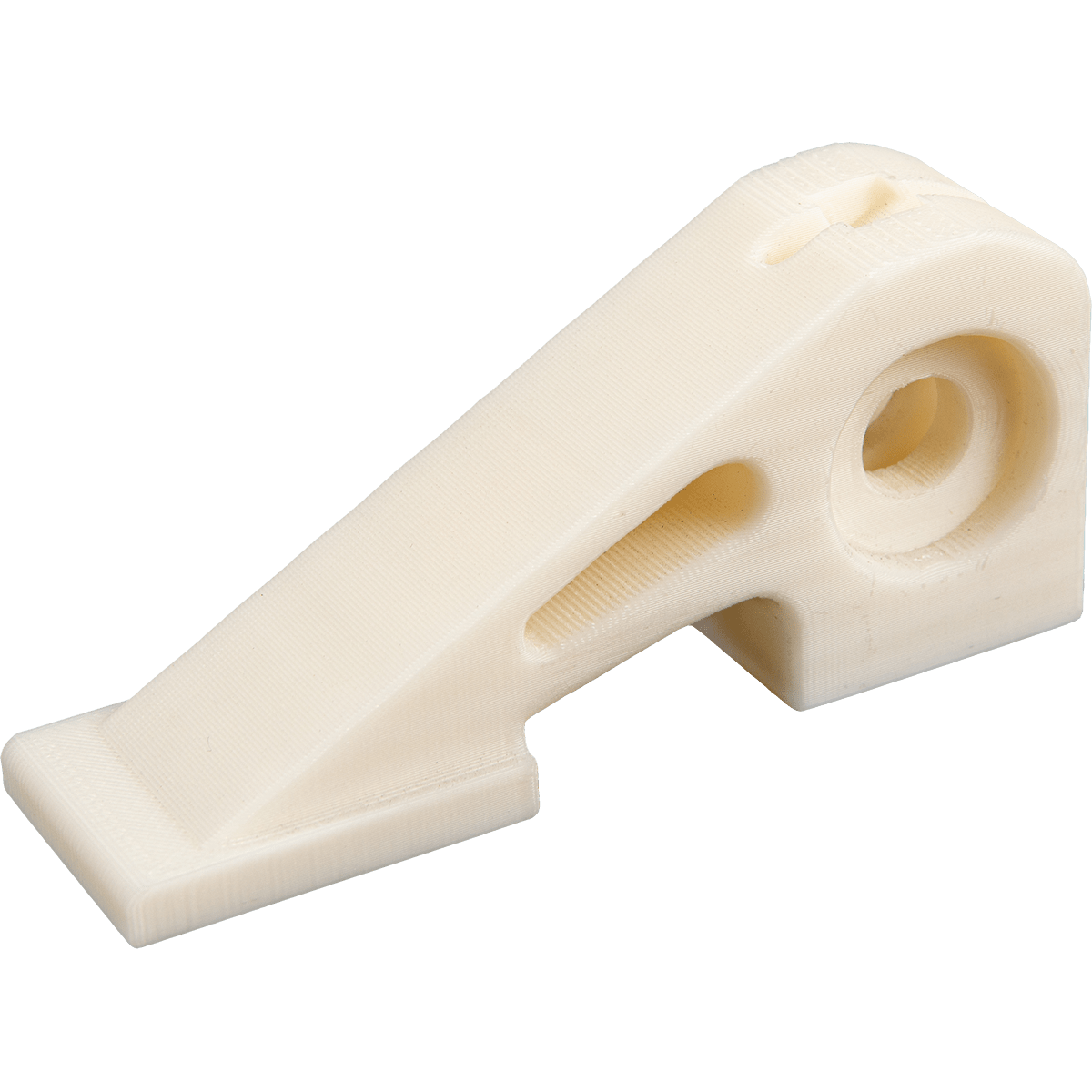

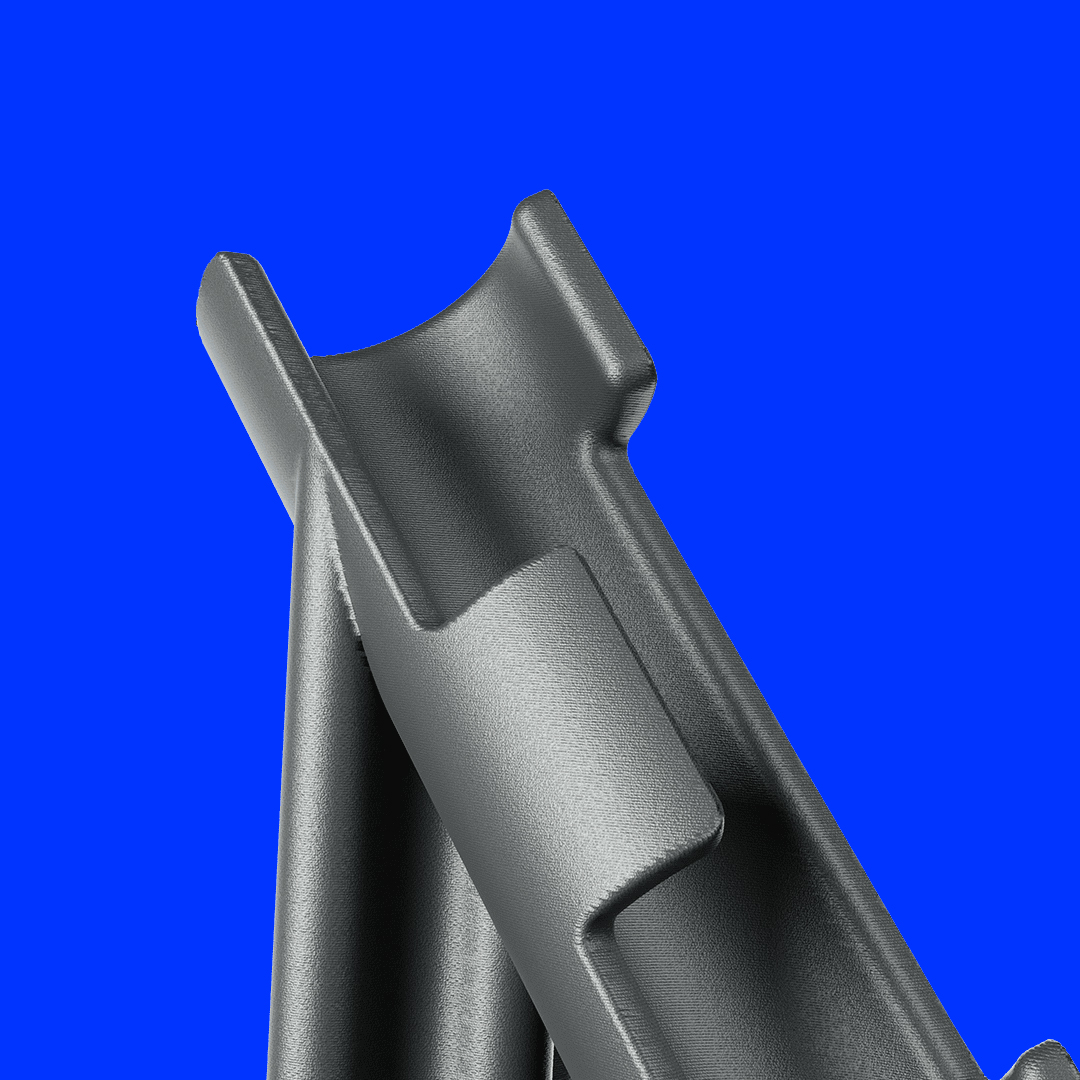

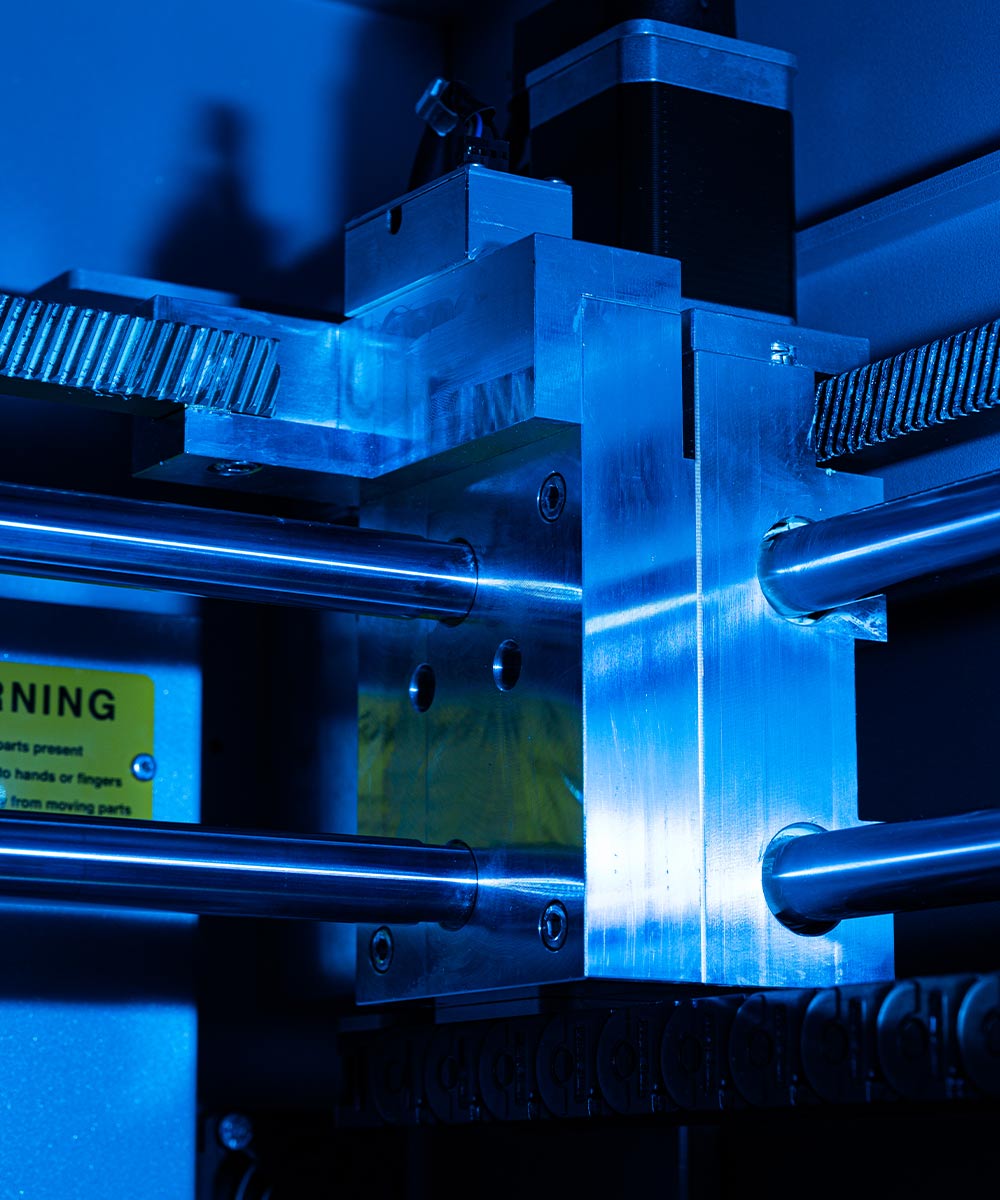

Accuracy and Repeatability

Roboze's patented movement system with gears, the Beltless System, has always been synonymous with repeatability and accuracy. The Roboze Plus PRO guarantees 3D printing precision of 15 microns and repeatability of the printed parts over time.

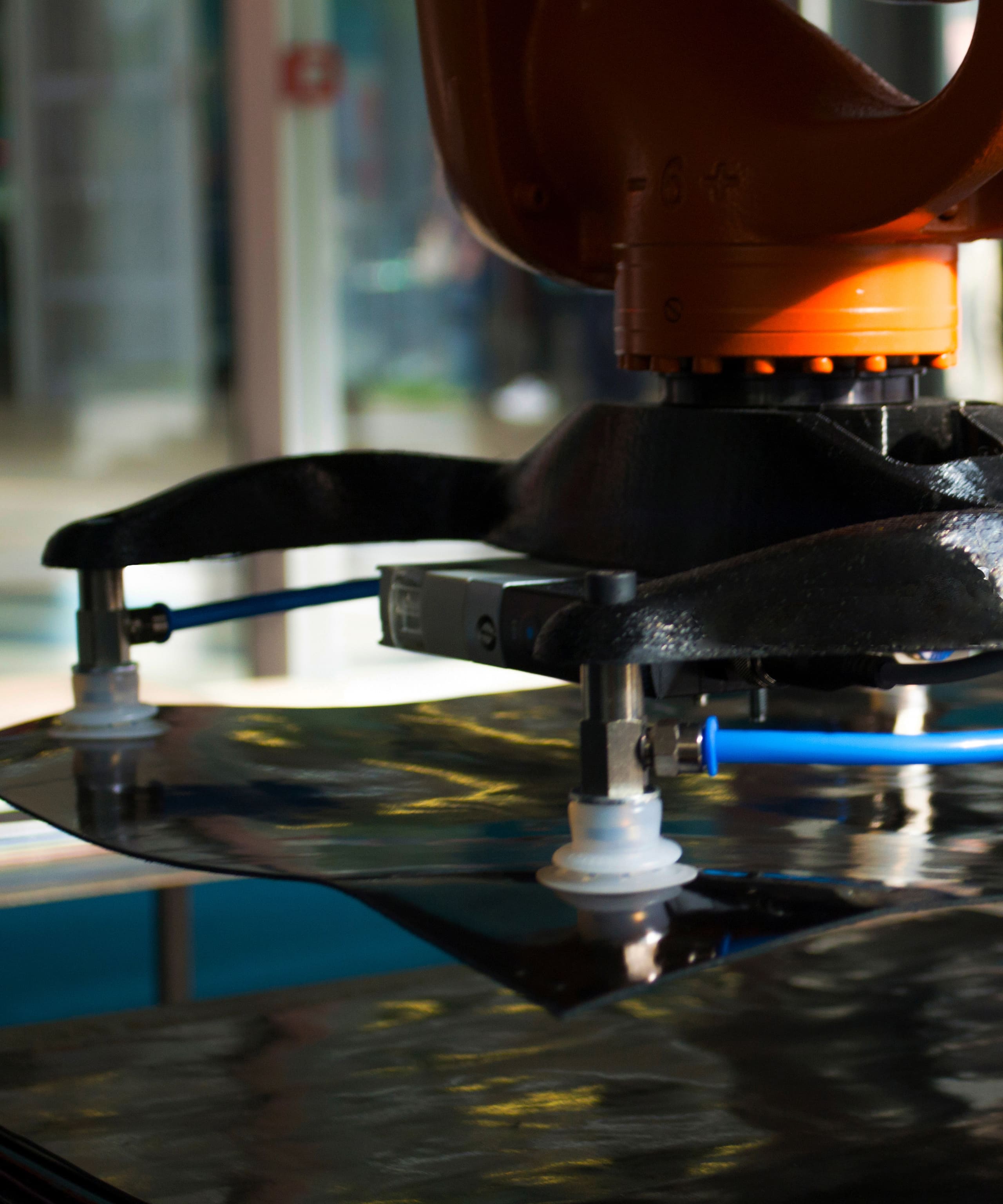

Versatility from all angles

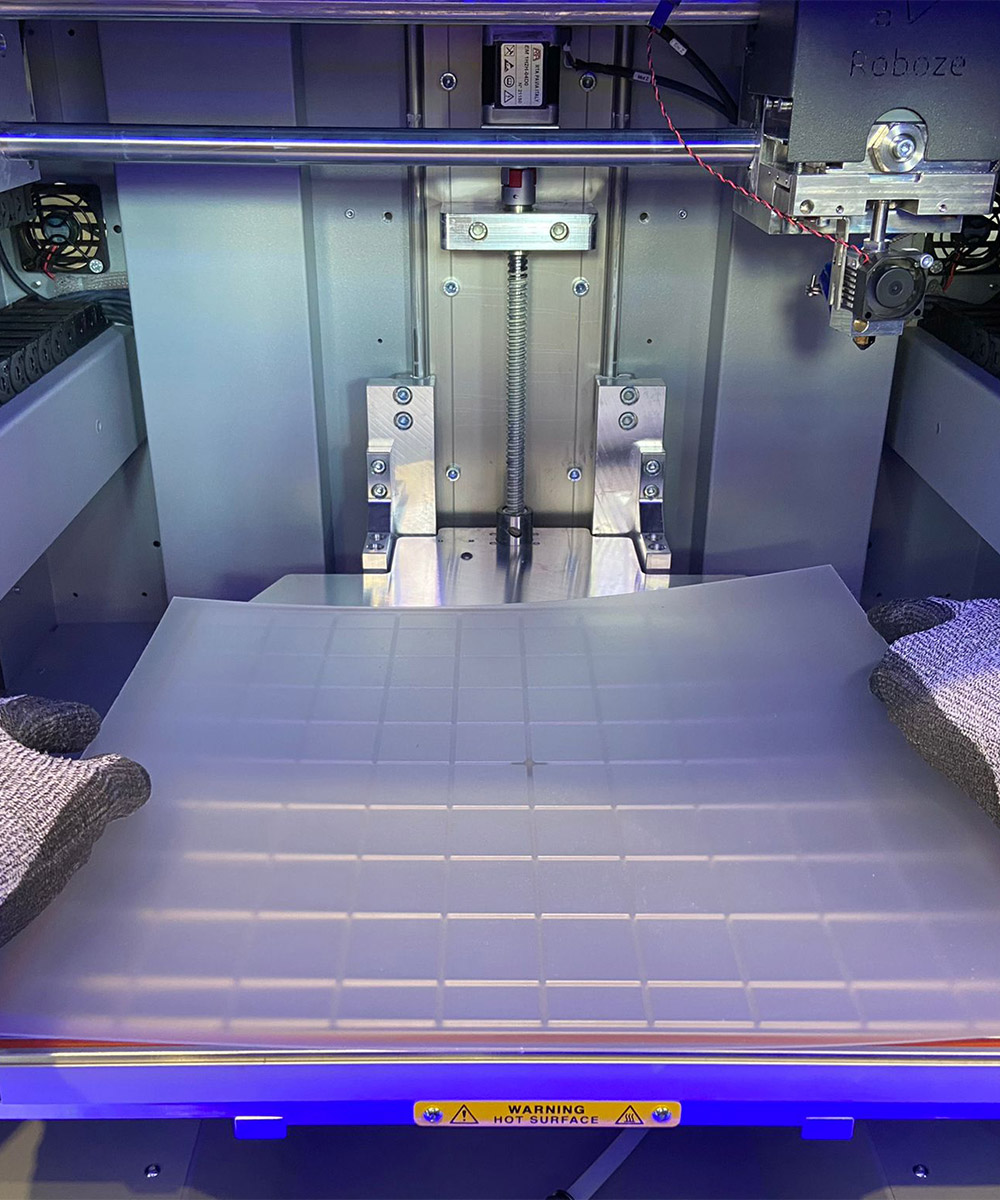

Roboze Plus PRO reaches high temperatures. The printing bed, with a volume of 11.8x9.8x8.7 in (300 x 250 x 220 mm-xyz), reaches temperatures up to 302°F (150°C) which, together with the vacuum technology, guarantees stability and perfect adhesion of the printed components throughout the process.

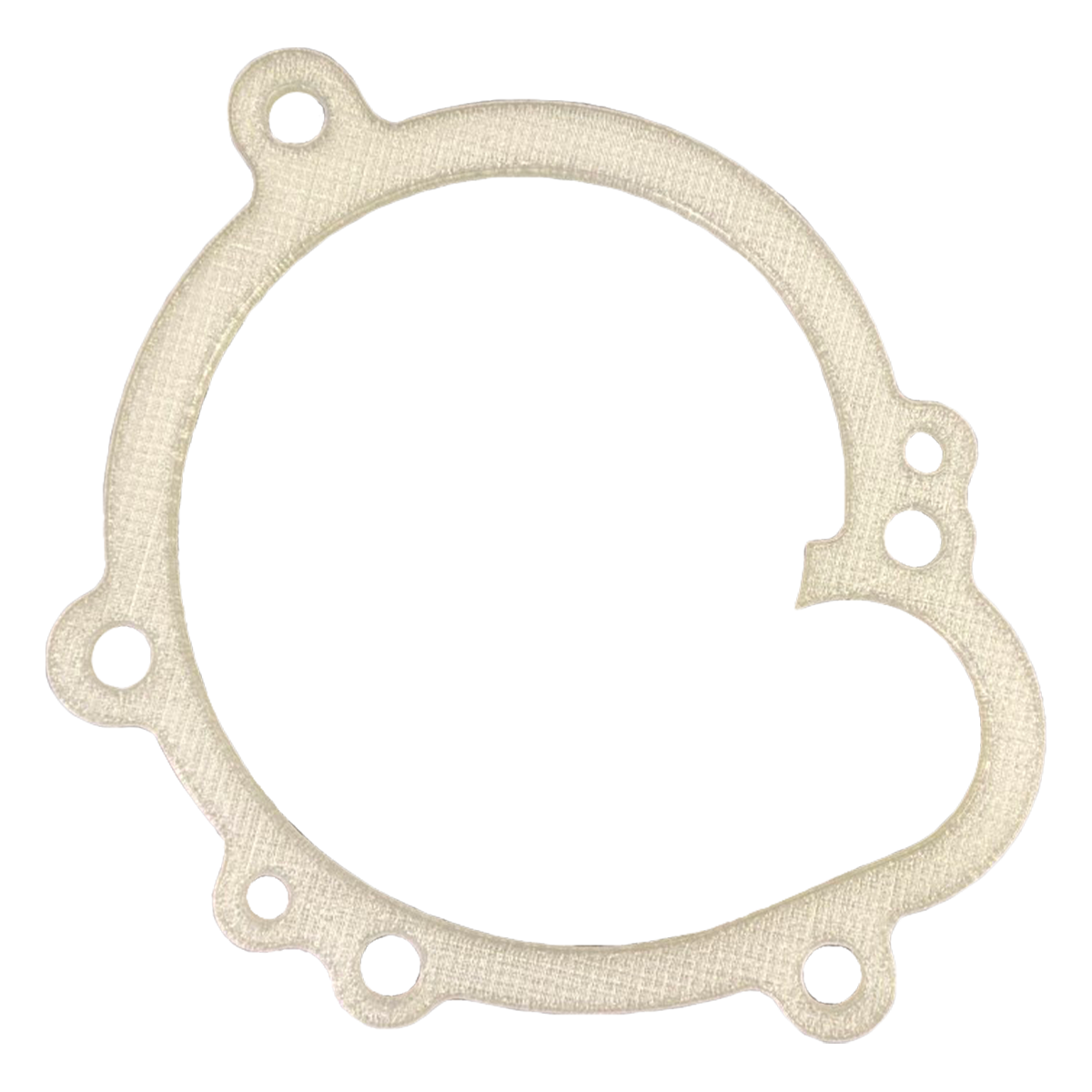

Quality above industry standards

The PRO series industrial 3D printers integrate the HT Dryer device which, together with the other innovative elements in the machine, has the function of preparing the material before 3D printing, drying and heating it, thus guaranteeing surface quality and mechanical performance of the parts produced.

3D printing materials

Super polymers engineered to fit your needs

Flexible, strong, extreme materials

Roboze Plus PRO industrial 3D printer processes a large variety of engineering polymers and super polymers. From aesthetic materials such as ULTRA-PLA and ABS, passing through flexible materials such as FLEX-TPU, arriving at super polymers such as PEEK, PEKK, ToolingX CF and Carbon PEEK. Thanks to the extreme versatility and performance of the super polymers associated with the printing profiles with the Roboze Prometheus software, you can create functional prototypes and finished components for extremely different applications, reducing time and costs.